Latest Post

How MacroFab Listens and Delivers

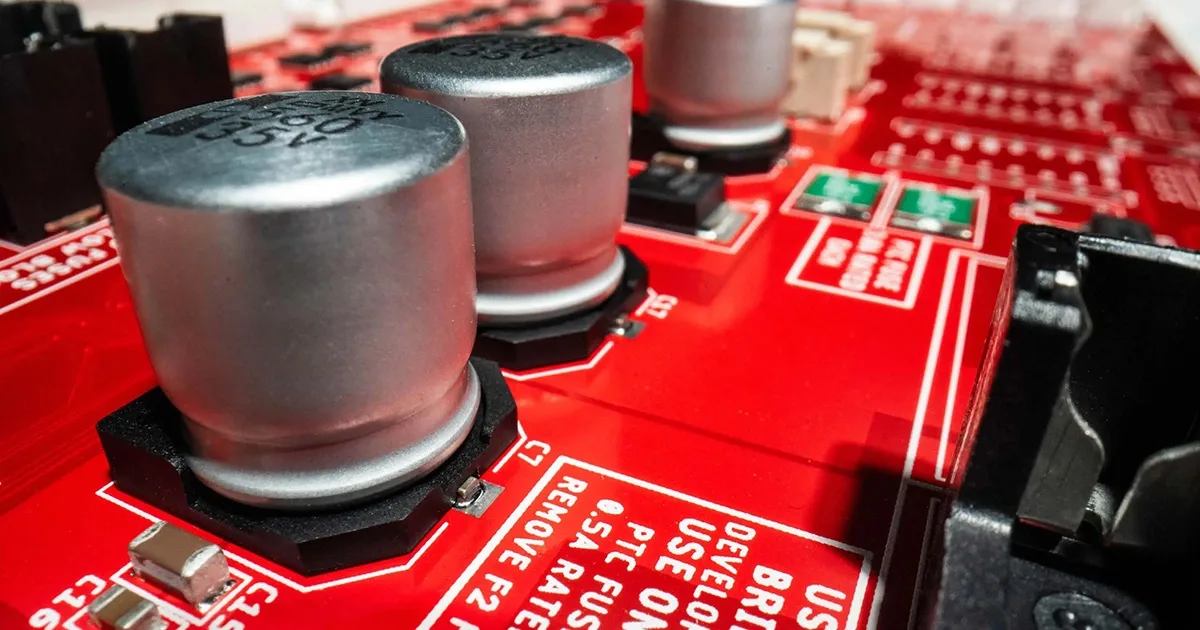

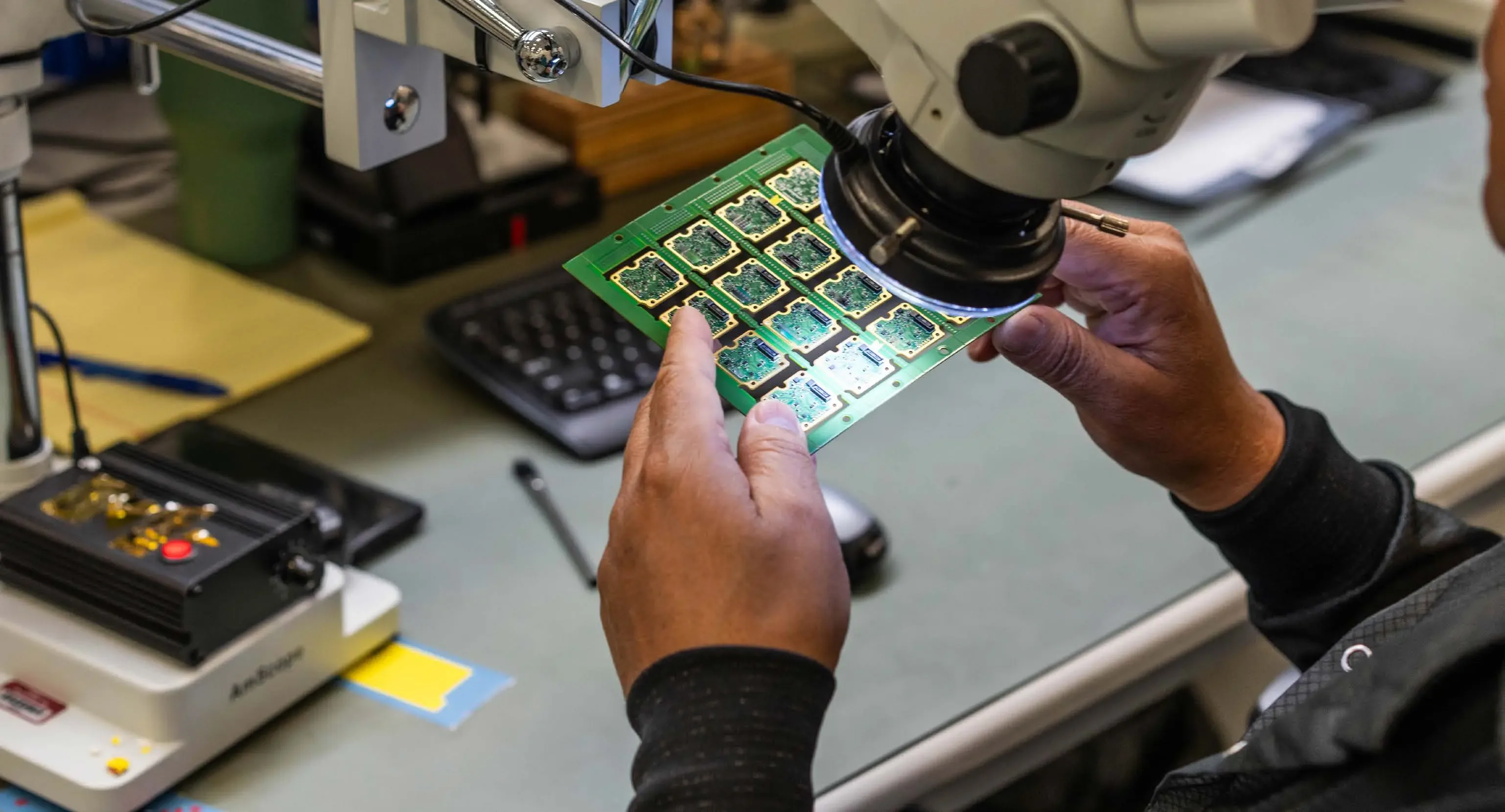

We’ve revolutionized the traditional PCB manufacturing process, offering a online platform supported by a network of high-quality North American factories.

July 25, 2024

Latest Post

We’ve revolutionized the traditional PCB manufacturing process, offering a online platform supported by a network of high-quality North American factories.

July 25, 2024

A discussion on how understanding impedance control can result in successful prototyping and manufacturing when choosing to work with MacroFab.

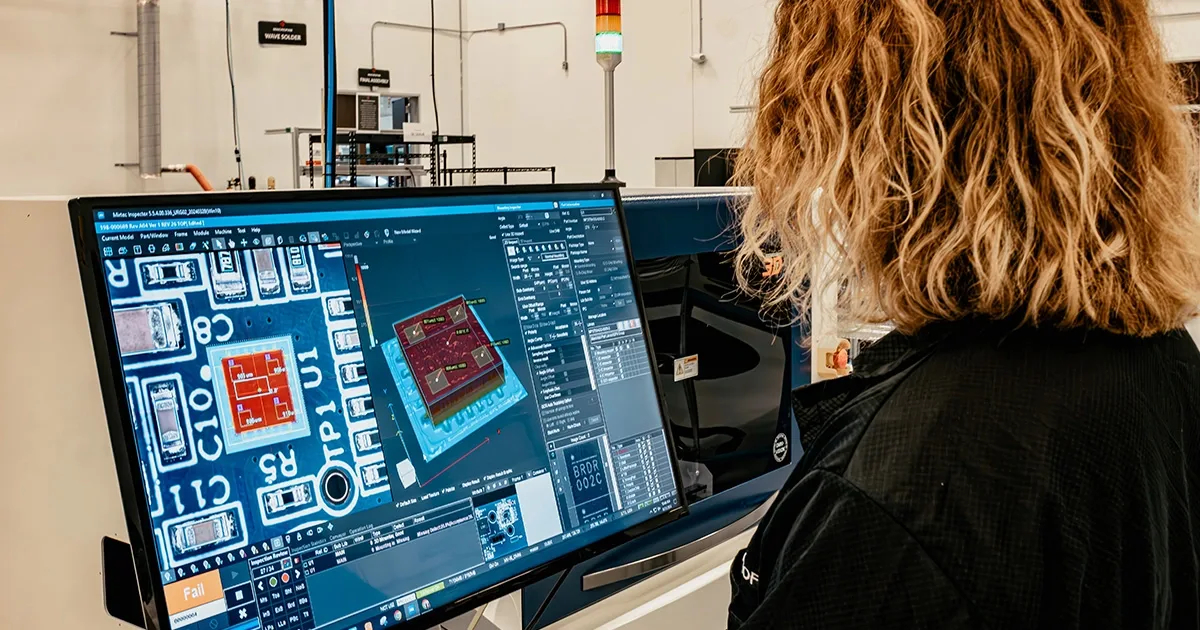

To prioritize delivering top-quality PCBs, this blog discusses the importance of AOI to meet the highest PCB standards.

This blog glances at how EMS is an effective services to produce a good design and sellable products. Being a great tool to turn ideas into reality.

This article explores how electronics and PCBAs contribute to the success of e-bikes today.

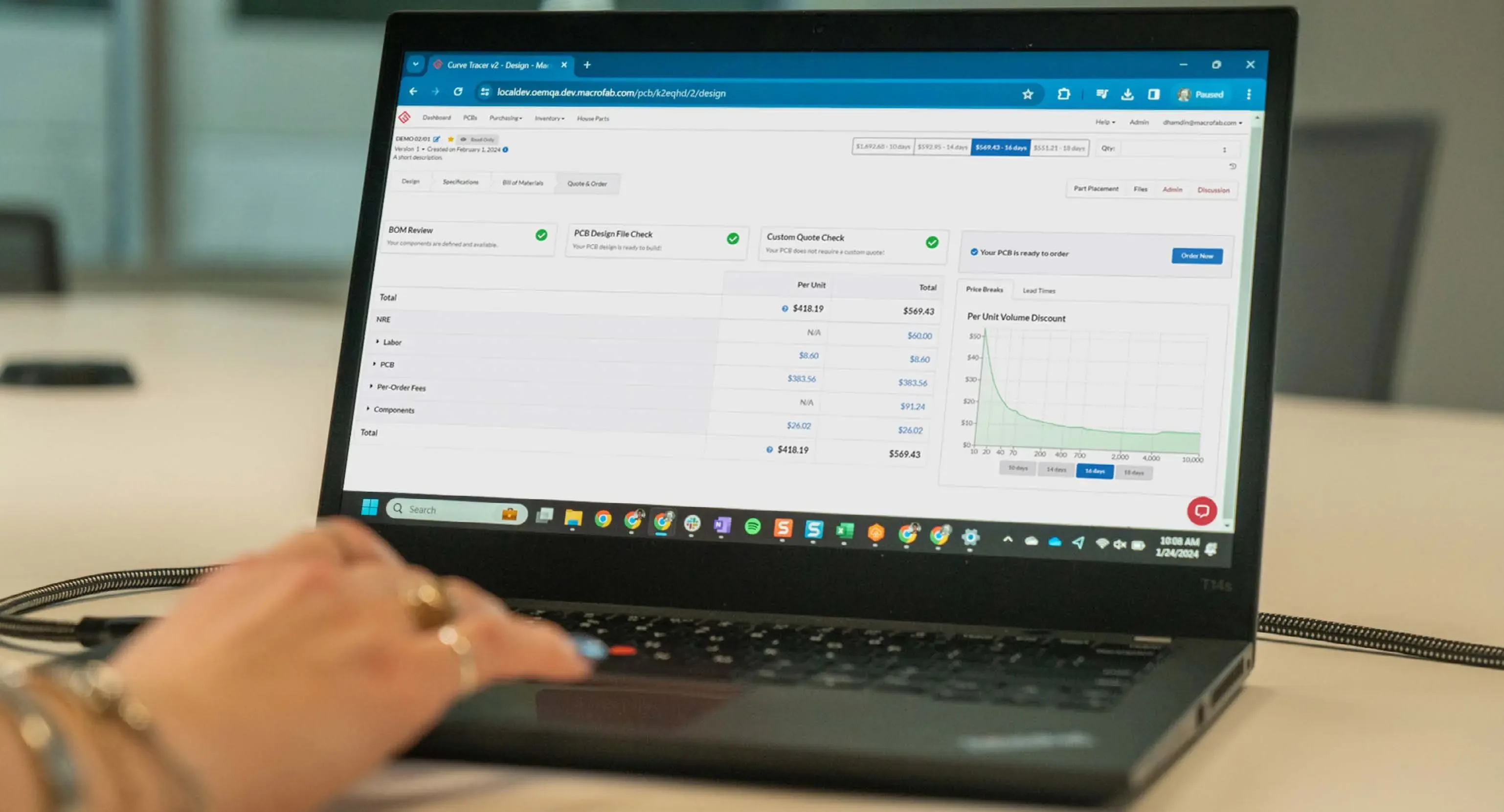

A glance at how MacroFab's platform can turn concepts into a real functional product. This can be done with the many services that MacroFab offers.

With the rise of water scarcity and climate change, modern agriculture faces some concerning potential dangers. PCBAs can optimize the irrigation systems.

This blog will discuss how MacroFab can help customers in their PCB production experience through clear communication in a high-octane environment.

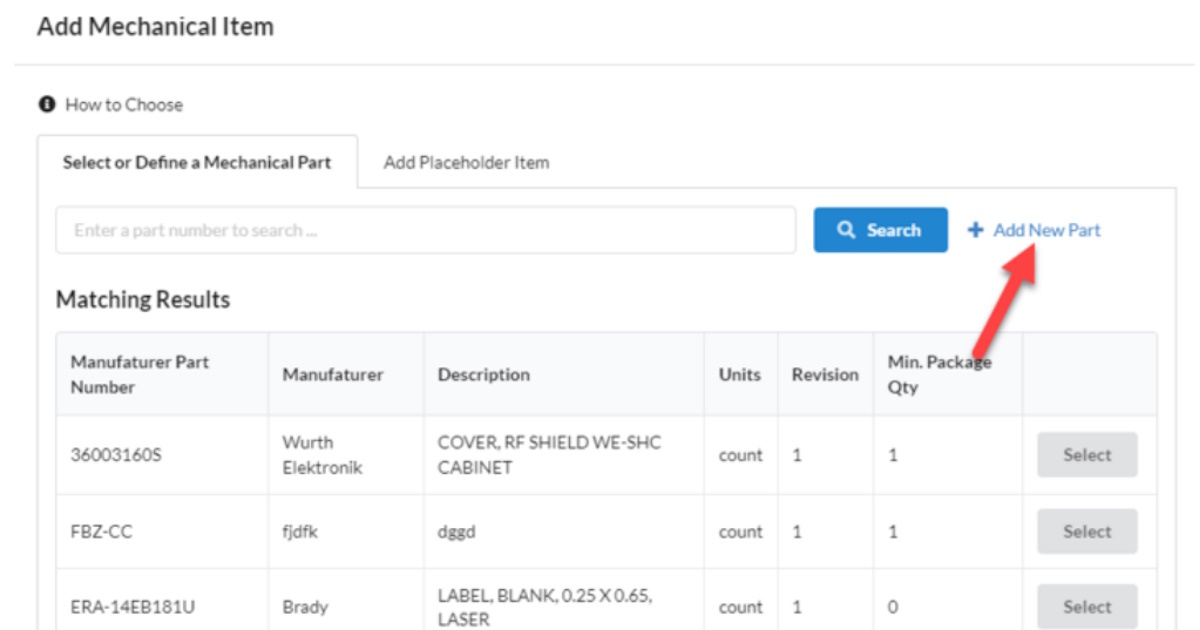

Manage Mechanical Bills of Materials (MBOMs) with electrical BOMs in MacroFab's PCB platform. Streamline projects and save time with our new MBOM feature.

Enjoy these handpicked episodes designed to spark your imagination and fuel your passion for electronics.

Understanding the challenges and best practices in creating sophisticated sensors for real-time data collection for different industries.

Learn how to improve your next PCB prototypes as engineers push the boundaries of hardware technology to enhance debugging, testing, and general liability

Learn how to prevent signal integrity of drones that could compromise circuit stability and overall performance.

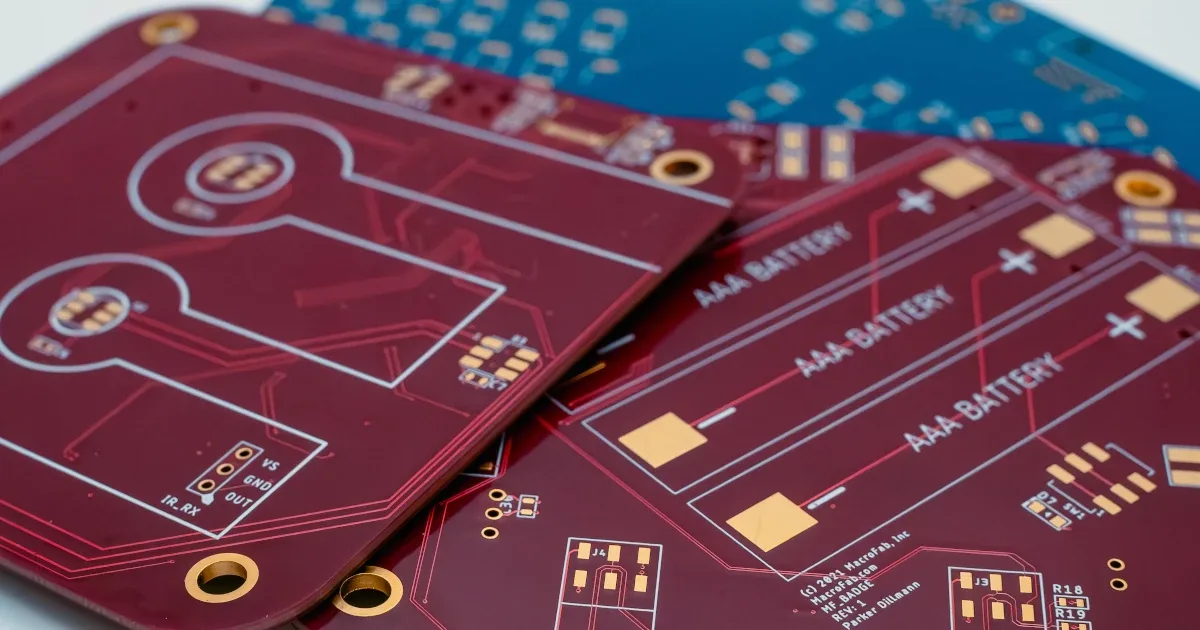

We are thrilled to announce the launch of our bare PCB board service to streamline your design workflow and help you bring your innovative ideas to life.

This curated list of top electronics podcasts is tailored for those trying to keep up with the rapidly evolving tech world.

A discussion about ITAR and the shared responsibility in protecting essential technologies and services vital to the security of our nation.

US raises tariff on Chinese semiconductors to 50% (from 25%). This could impact electronics engineers. Let's see how to prepare.

Providing a balanced perspective on how AI can revolutionize PCBA design while also looking at the challenges that we can face with this new technology.

Foster open communication to better embrace flexible BoM management and drive efficiency, quality, and innovation.

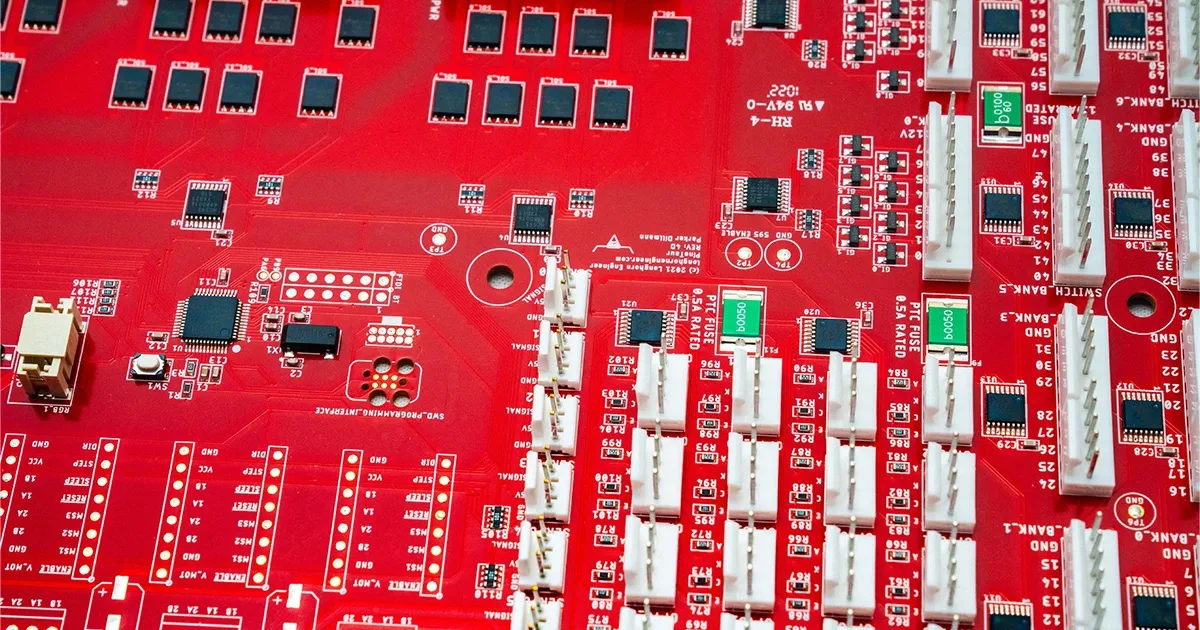

Making sure your prototype has the greatest chance of success the first time by outlining steps to take to get a prototype ready for manufacturing.

A discussion on why there is an advantage of choosing MacroFab and how they can supply the right manufacturing solution for companies of all sizes.

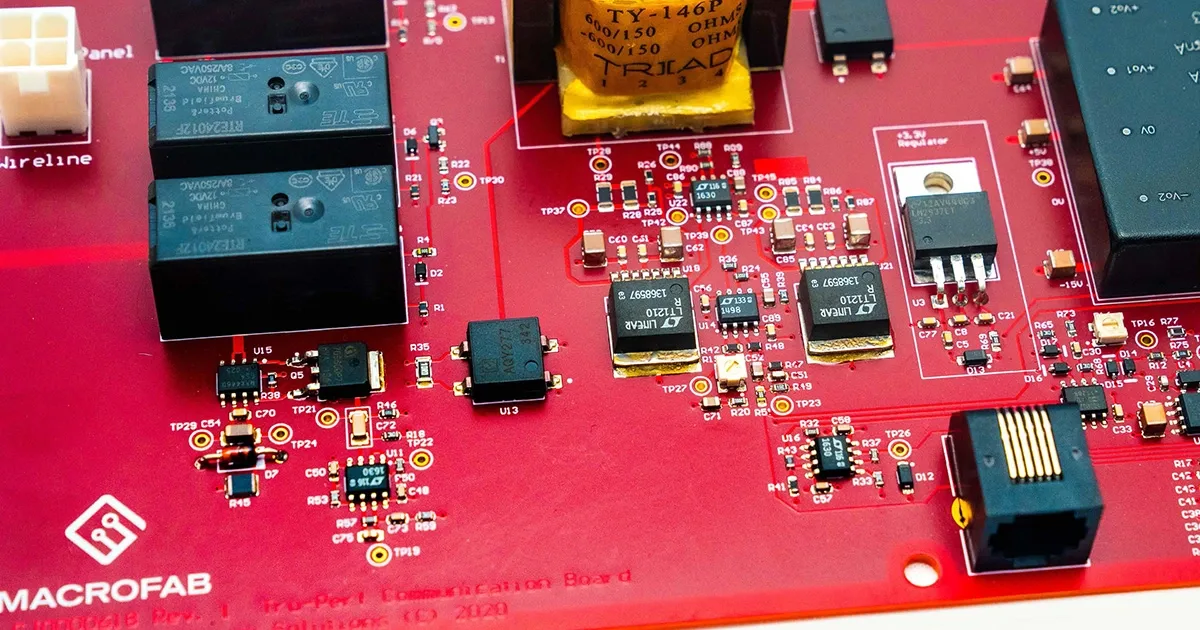

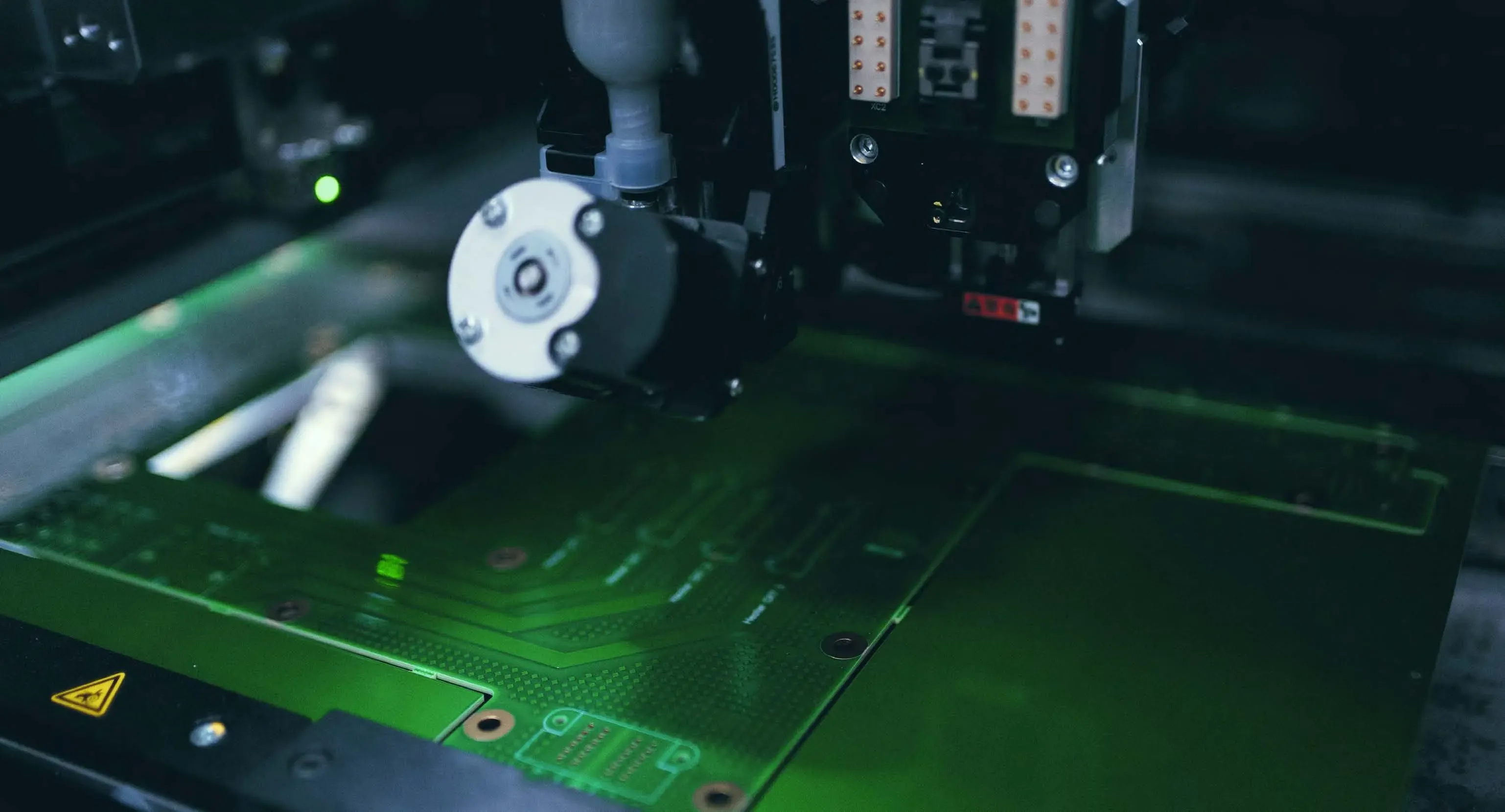

A discussion about the improvements and innovations of solder paste printing technology and their impact on the electronics manufacturing industry.

A discussion on cable assemblies and wire harnesses and their role in box builds.

Companies should create unique vendor relationships with numerous international suppliers due to the necessity of having to source components globally.

A display of some new features for the platform that enhances the the management of inventory and material at MacroFab.

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.