Navigating Sustainability Challenges in Electronics Manufacturing

Poorly regulated PCBA manufacturing can contribute to environmental damage, including ozone depletion, freshwater contamination, and algal dead zones.

PCBA Design Handbook - 2023

With this 75-page resource, you will have the expertise to excel in the fast-paced electronics industry.

Checklist: Do You Know How to Spot Counterfeit Parts?

Worried about counterfeit electronic parts infiltrating your supply chain? Counterfeit parts can compromise security and reliability of electronic systems.

Risk Management Strategies for Smaller Electronics Companies

Discover ways to minimize potential risks and protect your business from unforeseen events.

Making American Electronics Post-Pandemic: Reshoring is Key

This infographic provides information on the various reasons why companies worldwide are reconsidering their supply chains.

When Silos Work for EMS Design (and When to Break Them Down)

While silos work for farm products, they don’t always work for electronics manufacturing. Companies have been working to break down the silo mentality.

The Next-Gen Power Grid: Designing Systems for the Future

Technological advancements now allow us to rethink our approach to energy, with myriad benefits for individuals, businesses, and society as a whole.

Supporting American PCB Act of 2022: An Overview

The Supporting American Printed Circuit Boards Act aims to provide incentives and funding for domestic PCB manufacturing and research.

Can Your Business Afford a Delayed PCBA Product Launch?

Don't let poor collaboration cost you market share and revenue.

PCBA Hardware for Edge Computing: Why It’s On The Rise

Distributed enterprises are pushing computing technology to the edge. Discover the why and how of edge devices.

Impact of Wearables on PCBA Design: Their Past and Future

A look at wearable technology's impact on PCBA design, and how the wearable market is evolving.

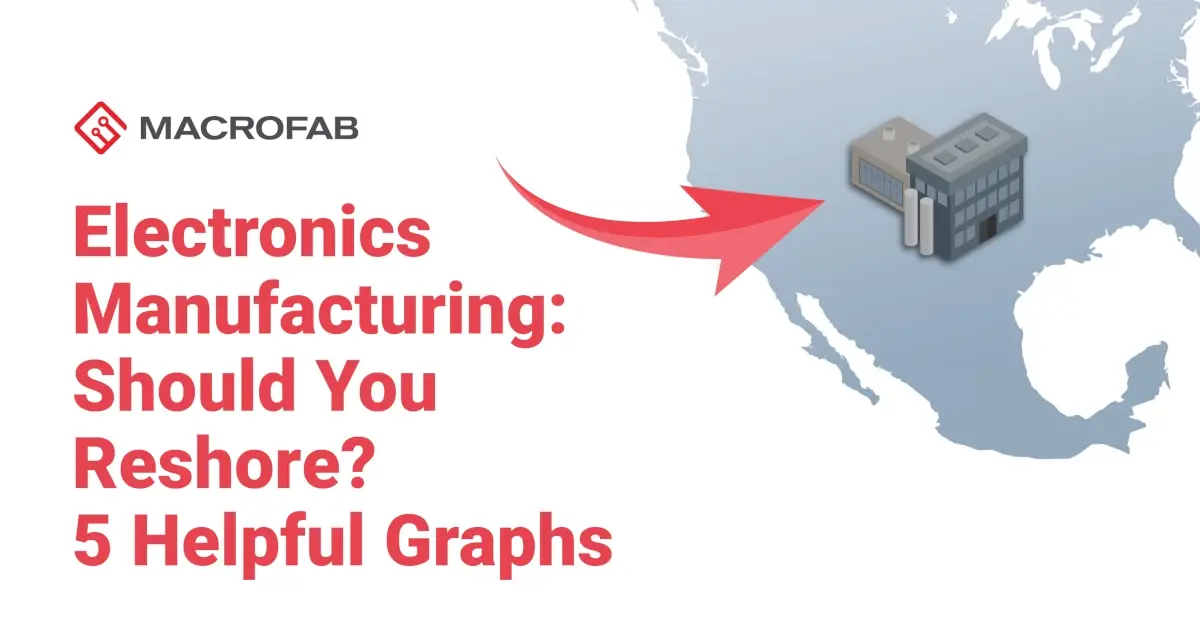

Should You Reshore Your Electronics Manufacturing?

Inside, you'll find five helpful graphs that will give you a clear understanding of the current trends and advantages of reshoring.

Recovery After COVID: How Electronics Supply Chains Have Changed

Supply chains have changed; are you ready for the challenges of tomorrow?

How to Optimize PCBA Power Transfer with Parallel Impedance

PCBA designs get smaller, faster, and more complex every day. How prepared are you?

Electronics Supply Chain Trends That Will Shape 2023

A focused analysis of factors affecting electronics manufacturing.

PCBA Cost and Complexity Design Factors You Should Know

Late-shipped products can reduce your profits by 33%. Don't make these common PCBA design missteps.

What’s Holding Your Electronics Product Launch Back

Don't let your customers down with a late product launch. Stay on schedule with these strategies.

Engineer’s Guide to PCB Manufacturing and Intellectual Property

What you don't know can hurt you. Protect your PCB intellectual property with these tips.

Ruggedized Electronics Design Basics: How to Increase Your PCBA Lifespan

Ruggedization is more than just a drop test. Make sure your equipment lasts.

The Complete Guide to Electronics Cloud Manufacturing

Find out how electronics cloud manufacturing can transform the way you do business.

Engineer's Guide To EVT DVT PVT Using Electronics Cloud Manufacturing

Find out how to keep your PCBA project on course with cloud manufacturing.

Design Faster, Improve Quality: Tips for PCBA Development

Your bottom line will suffer if you ship products late. You need a way to successfully accelerate product development during these challenging times.

Improve Electronics Procurement with Modern Strategic Sourcing Principles

OEM's can adapt to market trends, withstand disruption, maximize operational efficiency, and automate procurement processes.

The Electronics Product Development Lifecycle

Product owners are critical to the success of the electronic product development lifecycle, providing strategic direction and focus for the organization.