Circuit Break Podcast #187

Removing the Waterworld from Product Development

Related Topics

Remote Ownership

Tariffs hike hits electronics! Hear Parker analyze cost impact & debate chip kill switch ethics with Stephen. Plus, Parker's Python invoice hack!

Timing Tariff Modulations

We delve into the fascinating world of time modulation, discussing recent advancements in capacitor technology.

Riley Hall - Can Fictiv Make Beef Flags?

This week, Riley Hall of Fictiv joins the podcast to discuss how Fictiv connects engineers and designers to job and machining shops.

Other Resources

Circuit Break Podcast

Webinars

Videos

Tour MacroFab's ITAR-Compliant Facility

August 28, 2019, Episode #187

The MacroFab Engineering Podcast Design Contest sponsored by Mouser Electronics ends this Friday August 31st! Enter your Useless Machines now! We have cash prizes up to $1000 for the winners. Here's more information!

- Leads Marketing & Business Development for Fictiv

- True passion lies in transforming the manufacturing industry

- Having worked at Caterpillar, Autodesk, and Kaiser Aluminum, he has seen first hand the waste and inefficiencies that permeate the market

- From large Fortune 500 manufacturers to emerging technology startups, Mike has worked to solve a wide array of business challenges across the industry

- Experience with hardware entrepreneurs, manufacturing venture capital firms, large format additive manufacturing, closed-loop sensor networks, and fabrication of generative automotive chassis provide him a unique perspective on the rapidly changing landscape of manufacturing.

- At Fictiv he is currently focused on the disintermediation of traditional manufacturing supply chains and bringing distributed manufacturing to life for manufacturers of all sizes around the world

- Trade and Tariffs

- What has the impact of the recent Tariffs been on companies?

- What are some ways engineers can reduce the impact of the Tariffs?

- Counterfeit materials

- The Production Gap

- What is the production gap?

- Problems scaling up? Manufacturers?

- Staying on Budget

- Time Delays

- Quality

- How are companies overcoming these problems?

- People and Careers

- What does it mean to run lean?

- Do you think that the tariffs will have an emergent effect on lean operations? In the sense that to accommodate the increased cost of overseas business or switching to domestic fab, will business focus on other departments internally to squeeze out the fluff and fat of a product?

- Job Titles/Descriptions

- Happiness or Satisfaction with work?

- What does it mean to run lean?

Visit our Public Slack Channel and join the conversation in between episodes!

About the Hosts

Parker Dillmann

Parker is an Electrical Engineer with backgrounds in Embedded System Design and Digital Signal Processing. He got his start in 2005 by hacking Nintendo consoles into portable gaming units. The following year he designed and produced an Atari 2600 video mod to allow the Atari to display a crisp, RF fuzz free picture on newer TVs. Over a thousand Atari video mods where produced by Parker from 2006 to 2011 and the mod is still made by other enthusiasts in the Atari community.

In 2006, Parker enrolled at The University of Texas at Austin as a Petroleum Engineer. After realizing electronics was his passion he switched majors in 2007 to Electrical and Computer Engineering. Following his previous background in making the Atari 2600 video mod, Parker decided to take more board layout classes and circuit design classes. Other areas of study include robotics, microcontroller theory and design, FPGA development with VHDL and Verilog, and image and signal processing with DSPs. In 2010, Parker won a Ti sponsored Launchpad programming and design contest that was held by the IEEE CS chapter at the University. Parker graduated with a BS in Electrical and Computer Engineering in the Spring of 2012.

In the Summer of 2012, Parker was hired on as an Electrical Engineer at Dynamic Perception to design and prototype new electronic products. Here, Parker learned about full product development cycles and honed his board layout skills. Seeing the difficulties in managing operations and FCC/CE compliance testing, Parker thought there had to be a better way for small electronic companies to get their product out in customer's hands.

Parker also runs the blog, longhornengineer.com, where he posts his personal projects, technical guides, and appnotes about board layout design and components.

Stephen Kraig

Stephen Kraig is a component engineer working in the aerospace industry. He has applied his electrical engineering knowledge in a variety of contexts previously, including oil and gas, contract manufacturing, audio electronic repair, and synthesizer design. A graduate of Texas A&M, Stephen has lived his adult life in the Houston, TX, and Denver, CO, areas.

Stephen has never said no to a project. From building guitar amps (starting when he was 17) to designing and building his own CNC table to fine-tuning the mineral composition of the water he uses to brew beer, he thrives on testing, experimentation, and problem-solving. Tune into the podcast to learn more about the wacky stuff Stephen gets up to.

Special thanks to whixr over at Tymkrs for the intro and outro!

Related Podcasts

Making Money the Hard Way

The US Mint Denver produces 30 million coins a day. Denes, the tooling department manager, discusses with us how production at this scale functions.

Free Form Jazz Welding

Parker talks LED patterns on the MEP SAO, Stephen uses a CNC machine, and RadioShack returns?

Riley Hall - Can Fictiv Make Beef Flags?

This week, Riley Hall of Fictiv joins the podcast to discuss how Fictiv connects engineers and designers to job and machining shops.

Remote Ownership

Tariffs hike hits electronics! Hear Parker analyze cost impact & debate chip kill switch ethics with Stephen. Plus, Parker's Python invoice hack!

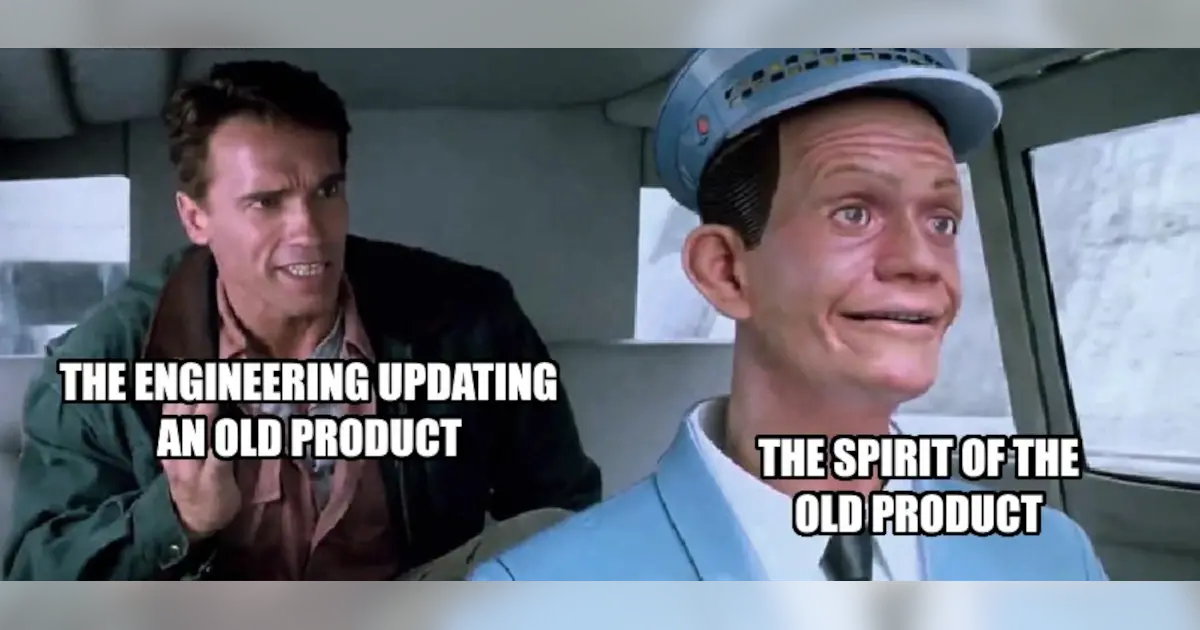

Keeping The Spirit Costs Extra

Revitalizing older products for next gen manufacturing can be tough. Does updating the design alter the spirit of the original? Oh and Tariffs.

Timing Tariff Modulations

We delve into the fascinating world of time modulation, discussing recent advancements in capacitor technology.

About MacroFab

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.