MacroFab Blog

We’re always looking for new ways to make it easier to build and order your PCBs. The challenge is that a lot of the applications and file formats that are commonly used in the manufacturing industry weren’t designed to accommodate a modern automated manufacturing platform, forcing people to have to fill in the gaps when critical information is missing.

One of the most time-consuming examples of this is assuring correct orientation of components. Between how the component is defined in the datasheet, drawn in your EDA tool, and physically packaged on carrier, a lot of time and care must go into ensuring that component orientation is correct. An especially frustrating example are LEDs: some manufacturers consider pin 1 to be the cathode, others the anode, and there isn’t a clear standard in the industry that everyone follows to make sure these parts are oriented correctly.

Automated Component Orientation

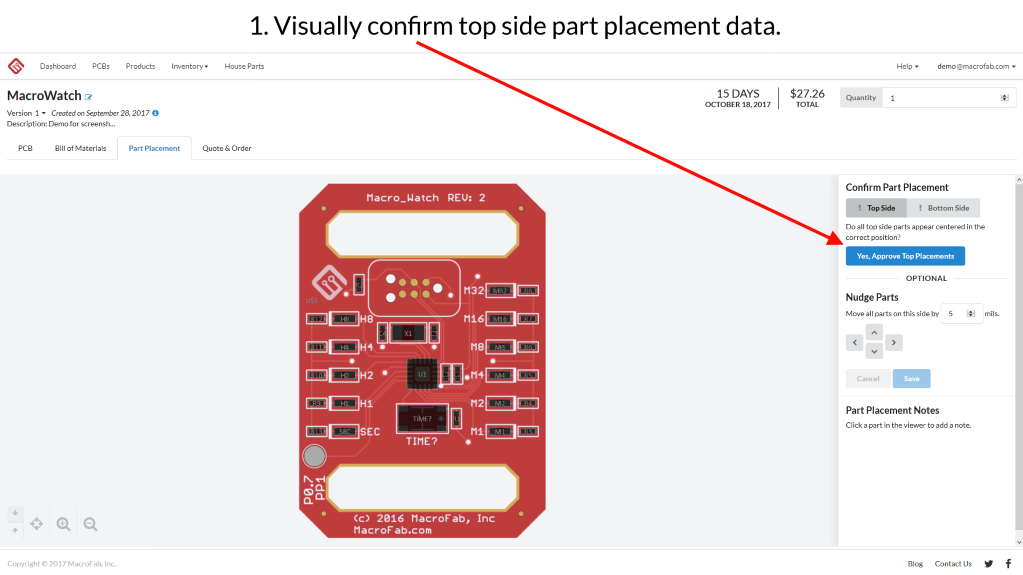

We decided the best way to solve this is to remove the burden of component orientation from our customers. All we now require is that you verify that the centroid data (center location) of your component is correct, and our automated manufacturing platform will take on the work of setting the orientation for you. Our system will automatically analyze the silkscreen data, paste data, and interconnectivity to determine the most likely orientation with feedback from our trained assembly techs before final production. If you wish to override your silkscreen, or a component can have multiple likely orientations and you want it to be oriented in a non-standard way (such as a FFC connector facing inwards), you can let us know by using the PCB Assembly Notes feature.

Tell us what you think about this new feature. Shoot us a tweet @macrofab. If you have any questions, feature requests, or feedback, don’t hesitate to let us know by emailing us at support@macrofab.com.

Related Topics

How MacroFab Uses Clear Communication to Improve Your PCB Production Experience

This blog will discuss how MacroFab can help customers in their PCB production experience through clear communication in a high-octane environment.

Improve Your Next PCB Prototype: Better Debugging, Testing, and Reliability

Learn how to improve your next PCB prototypes as engineers push the boundaries of hardware technology to enhance debugging, testing, and general liability

Prevent Prototype Delays:Essential PCBA Pre-Order Checklist

Making sure your prototype has the greatest chance of success the first time by outlining steps to take to get a prototype ready for manufacturing.

About MacroFab

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.