MacroFab Blog

Every great electronics product stems from a visionary idea.

What happens next varies depending on the business. Astute electronics developers prioritize a thorough developmental process to create quality PCBs, using a prototype service they can trust to identify and correct issues as they work toward building a PCB assembly that meets or exceeds user expectations. However, some companies insist their teams focus less on the quality of PCB fabrication and more on 24-hour turnaround times.

Yet PCB prototypes represent the early physical form of a new product idea. The main reason for prototyping PCBs is to evaluate certain functionalities or design traits before fully committing to production and should be made to the same quality standards. Ideally, the prototyping phase consists of rapid, low-volume iteration cycles followed immediately by quality manufacturing at scale.

Regrettably, some manufacturers lack the prototyping capabilities or even the desire to undertake such small-scale projects. Others only desire to prototype, leaving no way to move forward once early-phase work is complete.

To maintain profitability, these prototype-only fabs may utilize price-cutting tactics to attract buyers and fulfill more low-volume orders fast. The triple constraint triangle, however, says you cannot have it all at once. You can have it fast, good, or cheap, but you can’t have them all at the same time.

This explains why cutting corners during the PCB prototyping phase can cause problems in the future. A fast, cheap prototype won’t have the quality you’re looking for. And cheap PCB prototypes can ultimately incur higher costs for electronics developers when you consider the time, funds, and energy required to introduce a product at scale.

Besides the manufacturing process, cheap PCB prototypes can pose enormous obstacles for companies in the market – resulting in poor brand reputation, decreased brand loyalty, and a shrinking market share. Customers remember subpar products, and once you’ve lost a customer, regaining their trust is challenging.

In this article, we’ll delve into why it’s crucial to construct high-quality PCB prototypes from the start. We’ll highlight specific areas where electronics manufacturers tend to fall short, encompassing:

- Material quality

- Testing and verification

- Design detail

- Soldering quality

- Compatibility

There is little margin for error on any of these fronts. Success in electronics manufacturing requires being both careful and agile, a combination that is difficult to achieve. But investing in this, even if it implies spending more upfront on appropriate materials and robust processes, is worth it to avoid the pitfalls of a cheap PCB prototype.

Design

Checkpoint

Customers remember subpar products, and once you’ve lost a customer, regaining their trust is challenging.

The first area where electronics manufacturers may compromise during prototyping when creating a cheap PCB prototype is material selection. A less experienced PCB designer may be led to choose substandard materials during prototyping to minimize costs. This could translate into choosing inferior or even counterfeit components. Furthermore, if your cheap prototyping shop does not offer DFM (design for manufacturing), then you may unknowingly choose materials that create performance or reliability issues, or that do not meet your end regulatory requirements.

Interestingly, these subpar materials may not expose their limitations right away. They might suffice in limited use cases or short-term applications but may falter over time. Attributes like durability and thermal resistance can decline, increasing the likelihood that your PCBA will overheat with regular use. These issues will likely only surface after you have completed full production and shipped your product.

Moreover, electrical performance can deteriorate when inferior materials are employed. Thus, components have to work overtime to compensate. This overcompensation results in extra heat generation, leading to a multitude of subsequent problems.

Lack of Testing and Verification

During prototyping, it’s easy for electronics engineering teams to overlook testing and verification as they focus on achieving certain functionality. By failing to test a PCB in its entirety across multiple iterations, design errors can slip through, resulting in less reliable designs. When you work with a CM that is invested in your success beyond prototypes, the necessity for testing becomes apparent.

It is crucial for engineering teams to sustain testing and verification of prototypes as adjustments occur. A minor tweak in a seemingly unconnected part of the board can impact performance elsewhere. That’s why things like Design for Manufacturability (DFM) checks and ongoing testing are essential. Both help ensure that what electronics engineers are designing is viable from a manufacturing standpoint and free of preventable flaws.

Lack of Design Rigor

Design shortcomings are another common problem of cheap PCB prototyping. How likely is it that the least expensive fab house will point out design problems to you? Not likely. The cost of that service cuts into their profits.

PCBs should be of proper thickness for the anticipated use case. They should have wide enough trace widths to handle the projected electrical activity across the board. Design considerations should also incorporate testing and ensure that testing equipment can efficiently access all critical points.

Thermal management is another aspect that warrants careful thought - designers must proactively consider how to maintain the optimal temperature of their boards and components during peak usage. A fab house with an expert team may be able to point out thermal issues that you may have overlooked.

When left unchecked, design issues can cause damage to circuits or devices as a whole. Even in the early stages of materializing new product ideas, meticulous design reviews are vital. Engineering teams should evaluate and reevaluate designs constantly as things change, even during prototyping.

Bad Soldering

Soldering challenges are a recurring theme with PCB prototypes. It’s not uncommon to encounter difficulties due to a complex soldering process, potentially resulting in compromised components and connection issues. The prototyping stage is not exempt from challenges such as cold soldering and moisture intrusion during the soldering process.

Weak connections between components, an inherent risk in any intricate electronics work, can lead to electrical shorts and circuit malfunctions. In some instances, soldering irregularities could even create safety hazards for end users.

Ensuring that this doesn’t occur at scale is critical and highlights the importance of meticulous soldering during prototyping. Furthermore, working with the same CM for both prototyping and production at scale is advantageous, since any issues that surface can be resolved before moving to those higher production levels.

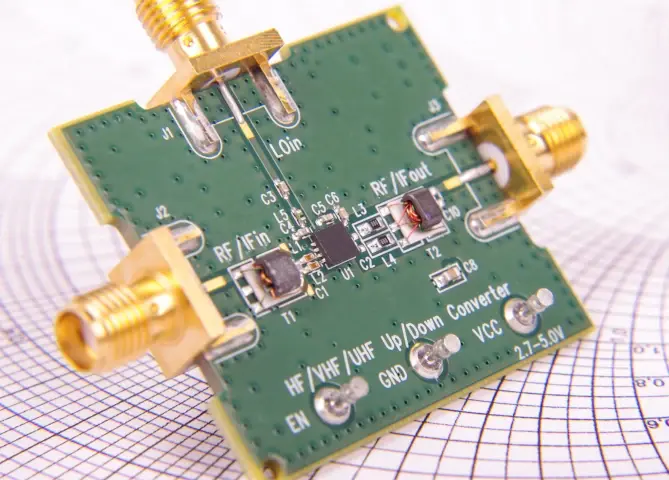

Compatibility Issues

Additionally, managing compatibility can pose a formidable challenge during PCB prototyping. Overlooking compatibility factors might sometimes result in significant rework or redesign as the production process unfolds. Having to reassess and modify PCB designs can be resource-intensive in numerous ways.

It’s imperative from the outset that electronics designers evaluate factors such as electromagnetic compatibility and interference to confirm their PCBAs effectively manage electromagnetic energy. It’s also important that the selection of materials aligns with the intended use case, especially when the PCBAs are designed for harsh environments. Compact PCBAs destined for smaller enclosures require a balance in the selection of components and cooling parts.

In the end, working with an expert team that can identify and fix these problems during prototyping is beneficial to your product and leads to a faster and more cost-effective prototyping process.

The Ultimate Cost of a Cheap PCB Prototype

Altogether, a cheap PCB prototype can cost much more than companies realize. Low-quality materials leave the door open for performance deterioration, safety hazards, and costly redesigns. As a result, companies may release electronic products that are unfit for long-term use. Your company is at risk of failure in today’s competitive electronics landscape if you commit this error.

Engineering teams should have full confidence that their products will be safe and reliable across their entire lifespans. Consequently, getting started on the right foot is vital. Cheap PCB prototypes aren’t worth it. Instead, work with a quality team that is invested in your success and ensure your new electronics products are built correctly from the start.

Related Topics

How MacroFab Uses Clear Communication to Improve Your PCB Production Experience

This blog will discuss how MacroFab can help customers in their PCB production experience through clear communication in a high-octane environment.

Improve Your Next PCB Prototype: Better Debugging, Testing, and Reliability

Learn how to improve your next PCB prototypes as engineers push the boundaries of hardware technology to enhance debugging, testing, and general liability

Prevent Prototype Delays:Essential PCBA Pre-Order Checklist

Making sure your prototype has the greatest chance of success the first time by outlining steps to take to get a prototype ready for manufacturing.

Get Quality Prototypes from MacroFab

Turnkey PCBA PrototypingAbout MacroFab

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.