Related Topics

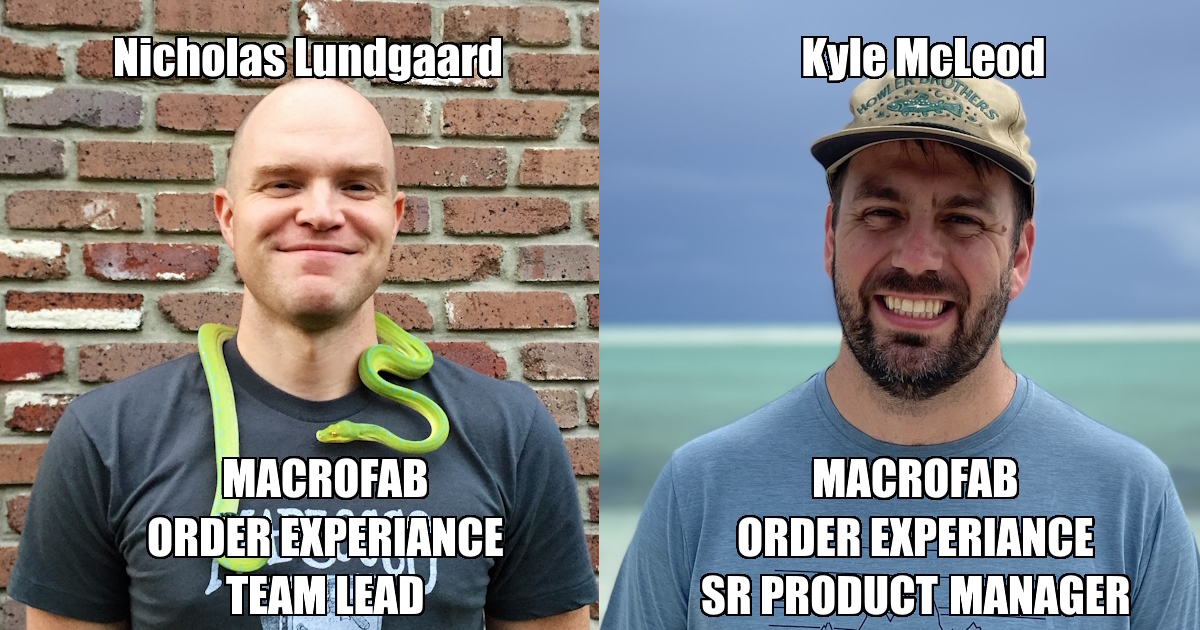

MacroFab Platform Updates from Kyle McLeod and Nicholas Lundgaard

The episode provides insights into MacroFab's efforts to make PCB manufacturing more accessible and efficient for their customers.

Tracing a Path for PCB Design Automation with Sergiy Nesterenko

Sergiy Nestorenko, founder of Quilter and former SpaceX engineer, discusses revolutionizing PCB design automation.

Entangled Steam

Parker and Stephen dive into the world of batteries, sparked by the BetaVolt BV100's claim of a 50-year lifespan.

Other Resources

Circuit Break Podcast

Webinars

Videos

Tour MacroFab's ITAR-Compliant Facility

February 3, 2021, Episode #262

Parker

- Robert Feranec

- Published a video about what to consider when selecting chips for your new board design.

- Don’t want to steal Robert’s content so go check him out.

- Hardware design and PCB Layout online course

- Published a video about what to consider when selecting chips for your new board design.

- Comprehensive Power Supply System Designs for Harsh Automotive Environments Consume Minimal Space, Preserve Battery Charge, Feature Low EMI

- Analog engineer Bin Wu and previous Linear Tech engineer Zhongming Ye writing an application note with linear tech devices.

- ‘An Ideal Diode Satisfies Automotive Immunity Norms’

- LT8672

- Active rectifier controller

- LT8672

- Why is all this needed?

- Car power is dirty

- Load dumps

- Cold cranking

- Pulses

- ISO 7632-2 is a negative spike whose peak voltage exceeds −220 V!

- Reverse Polarity

- AC Ripple

- Car power is dirty

Stephen

- Wurth Elektronik on Flex PCBs

- Basically Polyimide foil with deposited copper

- 3 ways to create a system (from page 2)

- Heterogeneous

- Homogeneous

- Partial Homogeneous

- Full flex and Semiflex

- Much Much easier way to create a 3d system design

- Added benefit of having a full panelized system

- Can test a full panel of designs all at once

- Test points can technically be on the flex

- Break and make

- Take the rails off of the PCB

- Flex-rigid boards

- Can be bonded to external layers

- Can be internal

- Can be rigid on one side or both

- Can be multiple layers

- Layout and routing

- Create a new layer in your EDA tool to define the Flex portion

- No vias in flex portion

- Use teardrops for added rigidity

- Use wider tracks where possible for added strength

- Do not change width in bend area

- Distribute conductors evenly

- Documentation

- Do it… Do it a lot

- In addition to the PCB gerber or ODB++ files include drawings

- A fab drawing that defines the flex pcb is very helpful

About the Hosts

Parker Dillmann

Parker is an Electrical Engineer with backgrounds in Embedded System Design and Digital Signal Processing. He got his start in 2005 by hacking Nintendo consoles into portable gaming units. The following year he designed and produced an Atari 2600 video mod to allow the Atari to display a crisp, RF fuzz free picture on newer TVs. Over a thousand Atari video mods where produced by Parker from 2006 to 2011 and the mod is still made by other enthusiasts in the Atari community.

In 2006, Parker enrolled at The University of Texas at Austin as a Petroleum Engineer. After realizing electronics was his passion he switched majors in 2007 to Electrical and Computer Engineering. Following his previous background in making the Atari 2600 video mod, Parker decided to take more board layout classes and circuit design classes. Other areas of study include robotics, microcontroller theory and design, FPGA development with VHDL and Verilog, and image and signal processing with DSPs. In 2010, Parker won a Ti sponsored Launchpad programming and design contest that was held by the IEEE CS chapter at the University. Parker graduated with a BS in Electrical and Computer Engineering in the Spring of 2012.

In the Summer of 2012, Parker was hired on as an Electrical Engineer at Dynamic Perception to design and prototype new electronic products. Here, Parker learned about full product development cycles and honed his board layout skills. Seeing the difficulties in managing operations and FCC/CE compliance testing, Parker thought there had to be a better way for small electronic companies to get their product out in customer's hands.

Parker also runs the blog, longhornengineer.com, where he posts his personal projects, technical guides, and appnotes about board layout design and components.

Stephen Kraig

Stephen Kraig is a component engineer working in the aerospace industry. He has applied his electrical engineering knowledge in a variety of contexts previously, including oil and gas, contract manufacturing, audio electronic repair, and synthesizer design. A graduate of Texas A&M, Stephen has lived his adult life in the Houston, TX, and Denver, CO, areas.

Stephen has never said no to a project. From building guitar amps (starting when he was 17) to designing and building his own CNC table to fine-tuning the mineral composition of the water he uses to brew beer, he thrives on testing, experimentation, and problem-solving. Tune into the podcast to learn more about the wacky stuff Stephen gets up to.

Special thanks to whixr over at Tymkrs for the intro and outro!

Related Podcasts

Dr. Duncan Haldane from JITX on Automating Circuit Design

Dr. Haldane on his background, the problems JITX is trying to resolve, & new auto-router plans. What's the deal with the "hyper-aggressive pogo-stick"?

Entangled Steam

Parker and Stephen dive into the world of batteries, sparked by the BetaVolt BV100's claim of a 50-year lifespan.

Tracing a Path for PCB Design Automation with Sergiy Nesterenko

Sergiy Nestorenko, founder of Quilter and former SpaceX engineer, discusses revolutionizing PCB design automation.

MacroFab Platform Updates from Kyle McLeod and Nicholas Lundgaard

The episode provides insights into MacroFab's efforts to make PCB manufacturing more accessible and efficient for their customers.

Laser Cutting Tolerancing

They may be known for being electrical engineers but on this episode, Parker and Stephen dig into the more mechanical aspects of their current projects

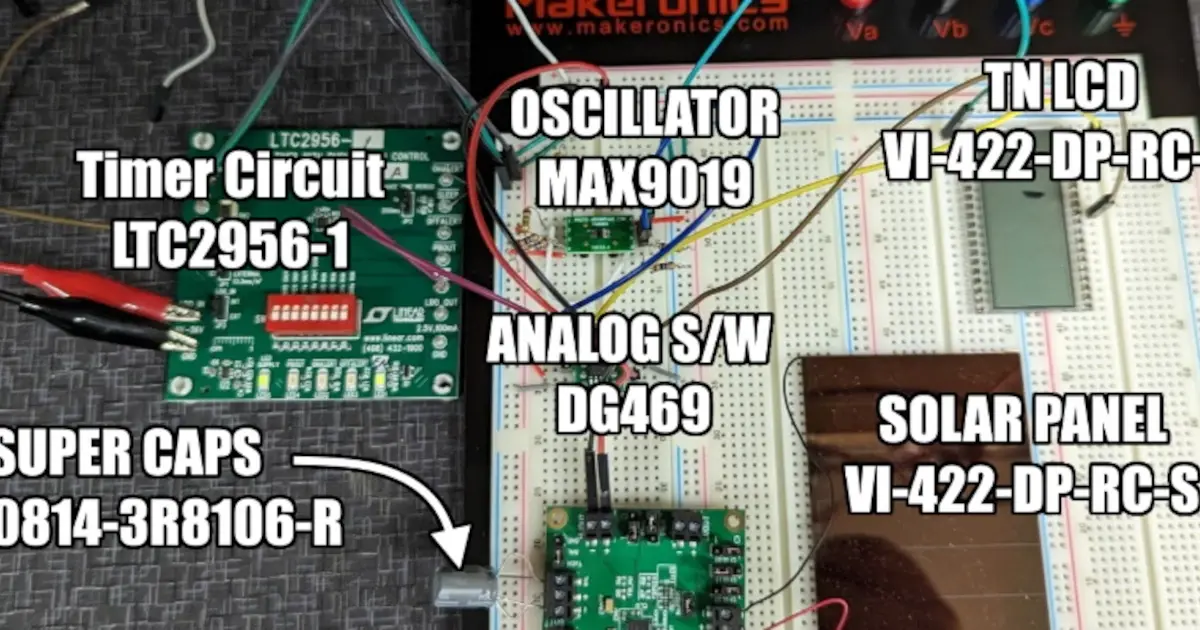

Breadboarding for Success

This week we are talking about Breadboards. Is breadboarding a circuit or design still applicable in today's SMT component dominated world?

About MacroFab

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.