MacroFab Blog

We’ve made the manufacturing approval process more seamless with updates to our PCB and Placement screens. In the PCB screen interface, you can now view the PCB rendering, specs and layers on one screen, and the Placement screen allows you to nudge parts and annotate them for easier communication and reduced delays in manufacturing.

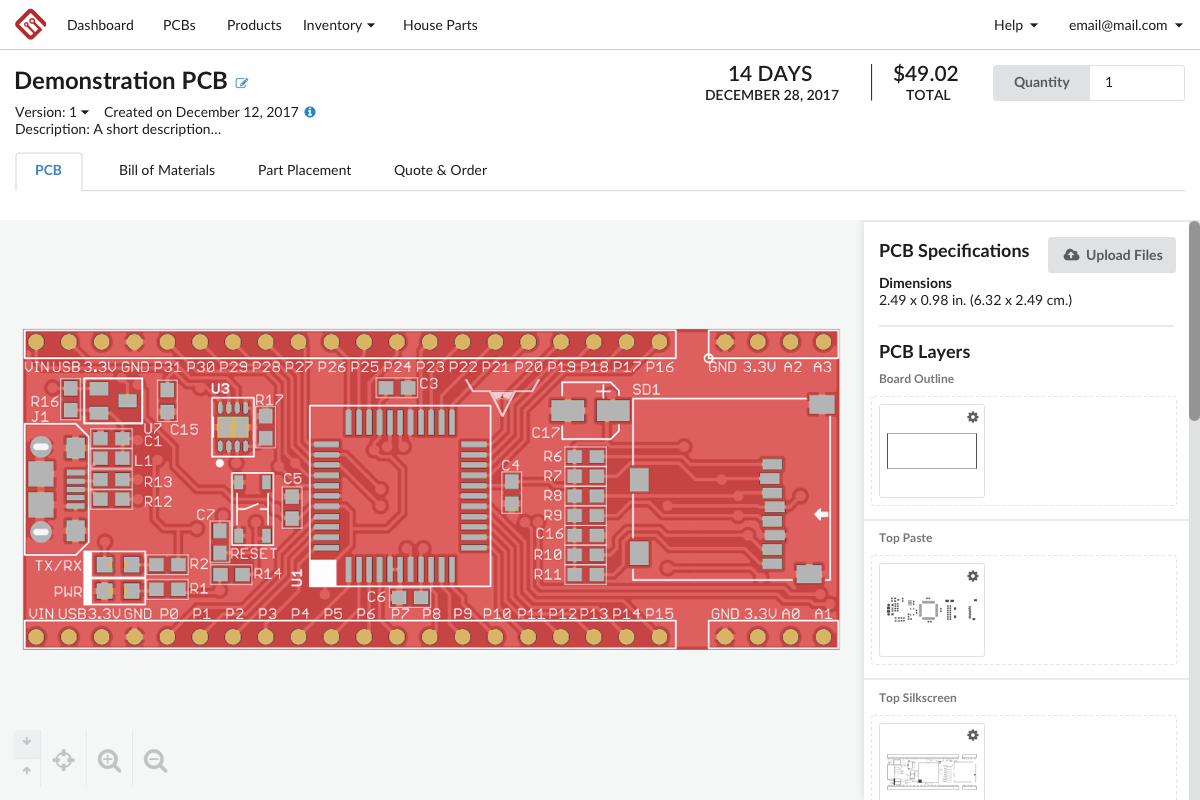

PCB Screen

The PCB screen now has a cleaner interface and gives you the ability to quickly view individual layers, or you can pin multiple layers so they are always visible for review. We’ve added a notifications feature, which will appear if a file is missing.

Review designs quickly and easily.

The workspace PCB screen shows a complete rendering of your file, where the specs and gerber files are on right sidebar, giving you a clear and complete view of your circuit board and files. On this screen, you can now tie multiple files to layers, and can move layers around or reassign them as needed. Here’s a quick recap of updates to the PCB screen:

- Live silkscreen and soldermask color display

- View individual layers by simply hovering over the thumbnail

- Pin multiple layers so they are always visible

- Include multiple files per PCB layer

- Move layers around or reassign them as needed by dragging-and-dropping

- Quickly flip your PCB over to view each side

These updates are designed to give you greater control and communication, earlier on in the manufacturing process. Viewing your files, specs, and layers on one screen will simplify the verification process of your board.

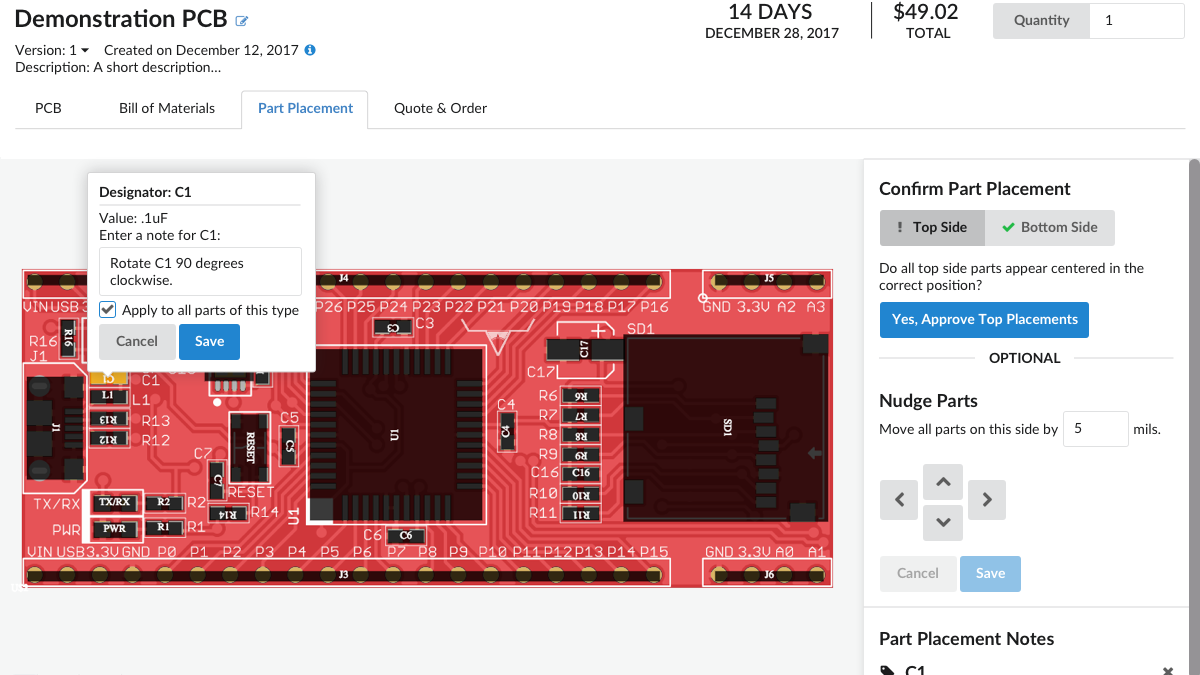

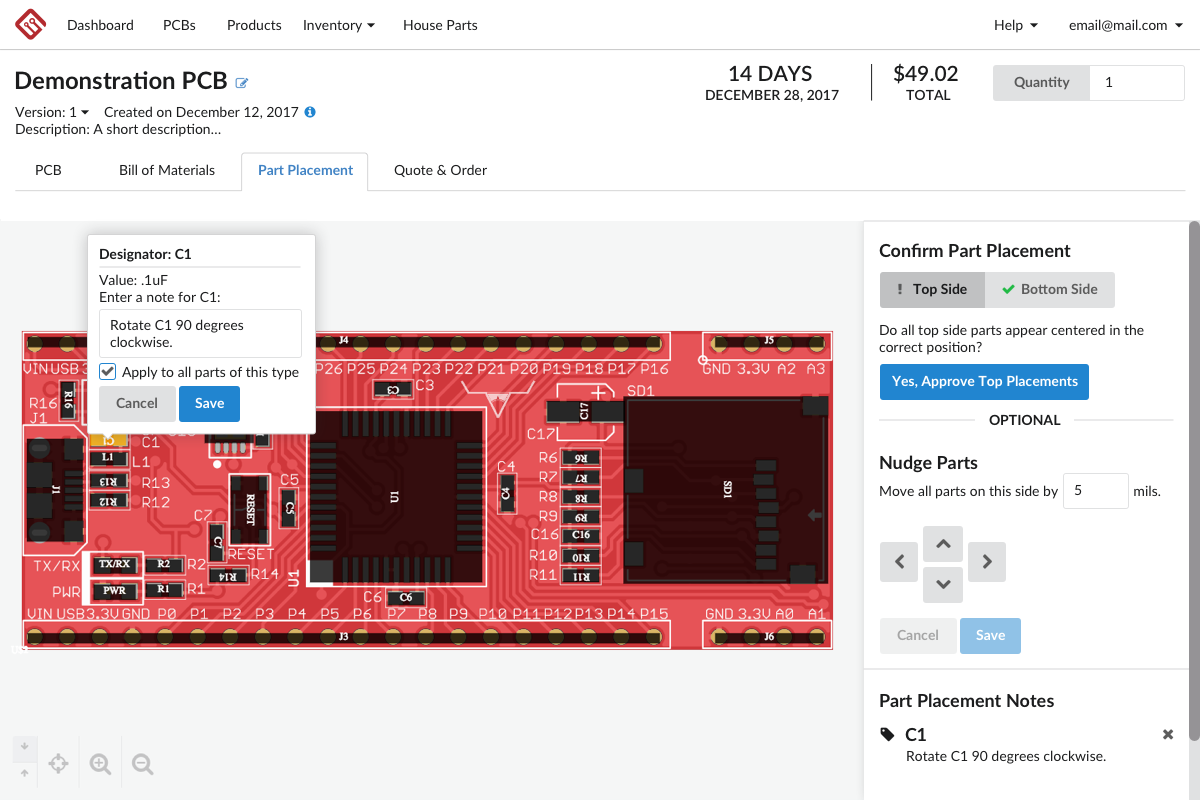

Placement Screen

View top and bottom sides of your board and approve part placement with greater ease than ever before. The updated Placement screen has been simplified with all navigation on the right sidebar.

Updated Part Placement Screen

If you notice that parts aren’t aligned properly, you can use theparts nudge feature to adjust as needed, without having to upload new files. This feature allows you to nudge all parts on one side, by a distance you determine. You can nowadd annotations to specific parts, giving you the ability to communicate changes to MacroFab on a per-component level.

Redefining electronics manufacturing

MacroFab is redefining the electronics manufacturing experience from a manual, time-intensive, and error-prone process performed by large teams of people, into a real-time, streamlined, and connected software-driven experience. With our globally competitive prices available instantly, and an interface that provides more information in a clearer format, it’s now easier than ever for you to take control of your projects.

For any questions or comments regarding these updates, please email support@macrofab.com

Related Topics

Streamlined Mechanical BOM Management

Manage Mechanical Bills of Materials (MBOMs) with electrical BOMs in MacroFab's PCB platform. Streamline projects and save time with our new MBOM feature.

MacroFab's Bare PCB Option Helps You Develop Products Faster

We are thrilled to announce the launch of our bare PCB board service to streamline your design workflow and help you bring your innovative ideas to life.

New Inventory Features Streamline Material Management at MacroFab

A display of some new features for the platform that enhances the the management of inventory and material at MacroFab.

About MacroFab

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.