Related Topics

Solder Slugs

We'll dive into nuances of working with contract manufacturers, specifically focusing on the responsibilities of both the designer and the manufacturer.

The Toilet Mountain of Social Media

The hefty topic of U.S. funding for 'digital twin' chips research under the CHIPS Act, comparing its budget to other big expenditures.

Wizard Trust Falls for PCB Footprints

Parker’s transition from Eagle to KiCad, facing challenges with library management and device layer integration. Also, the new MacroFab Quote Wizard.

Other Resources

Circuit Break Podcast

Webinars

Videos

Tour MacroFab's ITAR-Compliant Facility

June 24, 2016, Episode #21

- Dustin Holliday is our guest this week. He was on EP#13 of MEP. Dustin has been working on MacroFab’s KiCad parser and is currently researching the KiCad Python API Documentation.

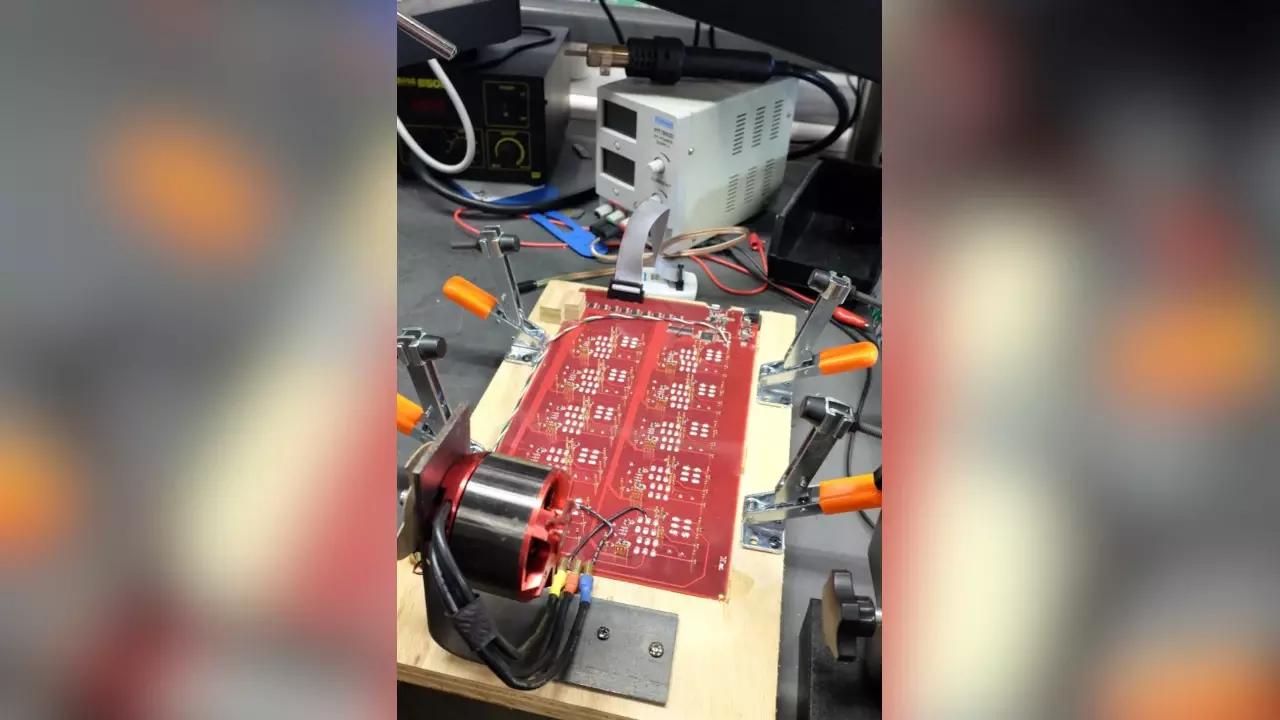

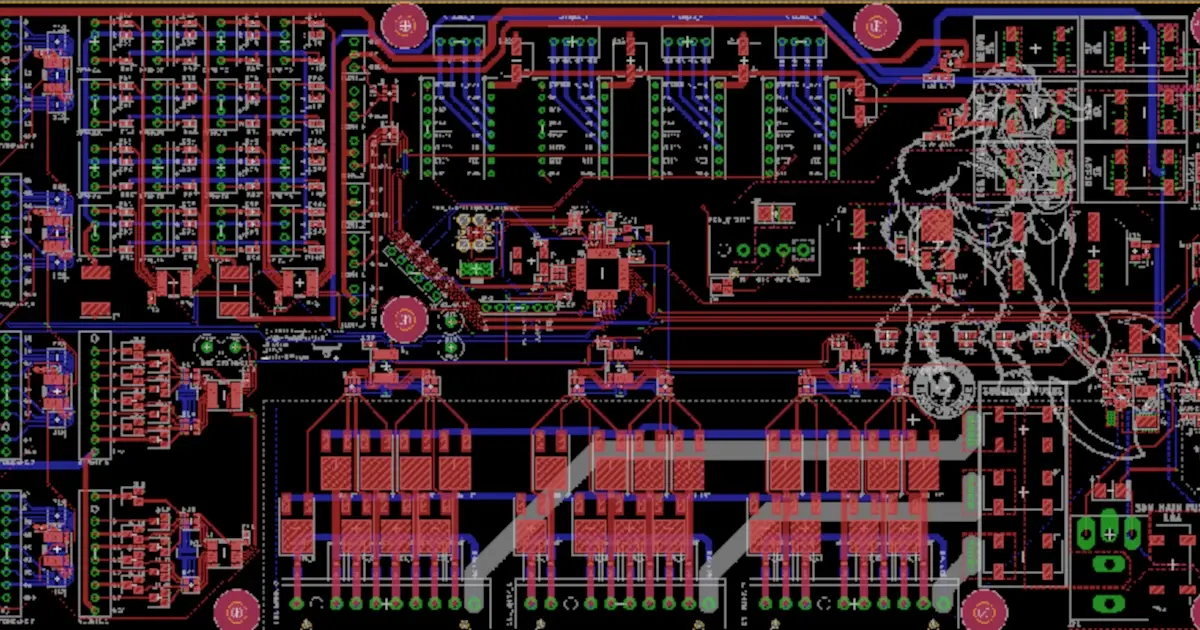

- Stephen and Dustin have also been working on a customer test fixture. The fixture can program an entire panel of boards with an ST Link. A brushless motor is attached to the fixture with an encoder to automatically test the boards. See Figure 1.

- Parker has been working on the Jig Of Destiny REV 3. Parts where ordered on Monday.

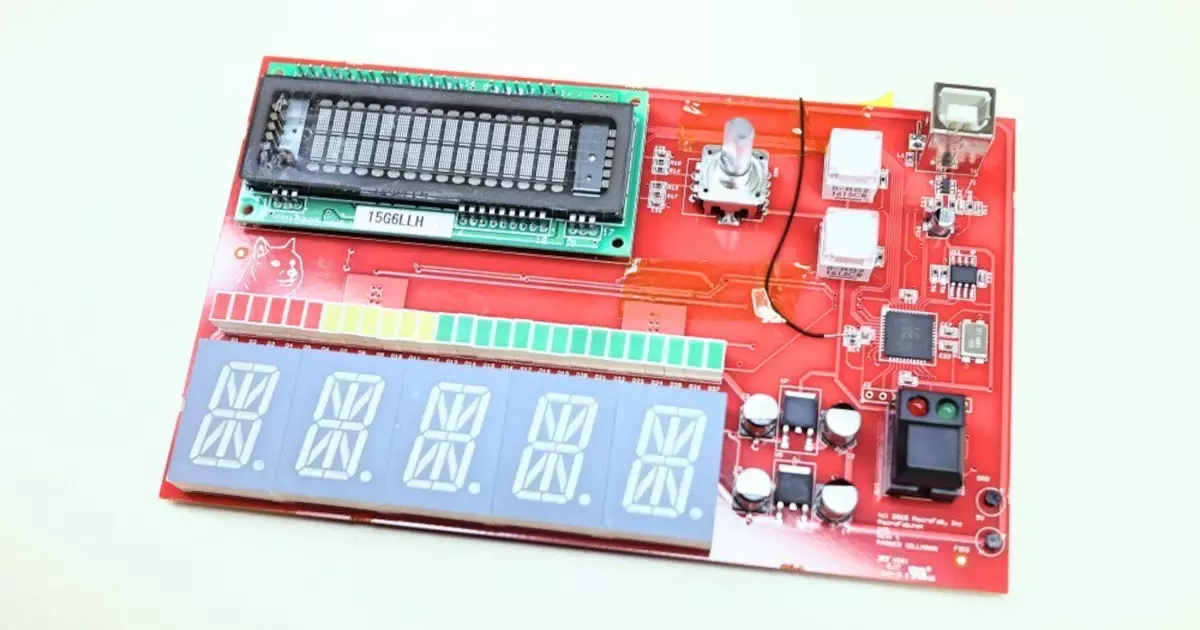

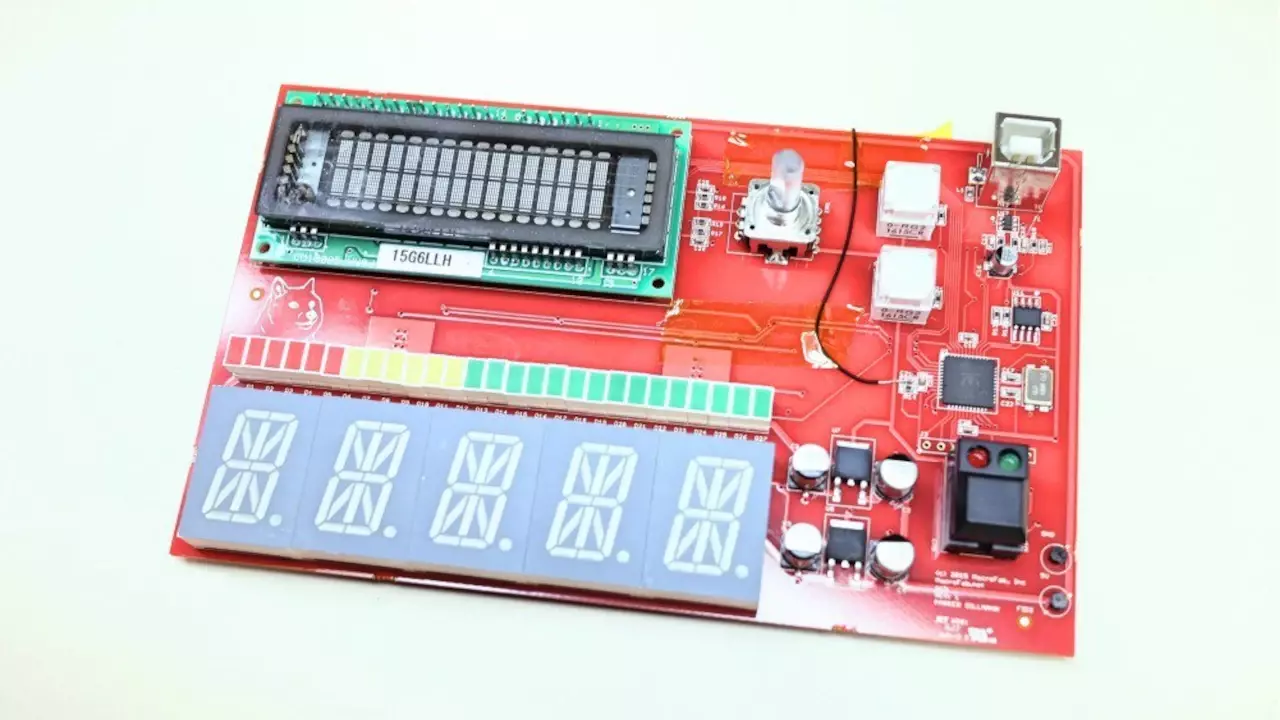

- The SSPS front test panel is complete with minimal hardware mods needed. Parker didn’t get to writing test code for it before the podcast but should have something to show on his twitter by Friday. See Figure 2.

- Parker got a I2C LCD display working. Ran into an issue but it turned out his SDA and SCL lines for the I2C protocol where backwards. He is using a Saleae DLA to debug the information. See his twitter post about it.

- Stephen has the analog test board for the SSPS ordered. Has a Pos/Neg rails of 35V, two OPA541 output opamps in parallel, and 0.08 Farads of capacitance. Beefy! See Figure 3.

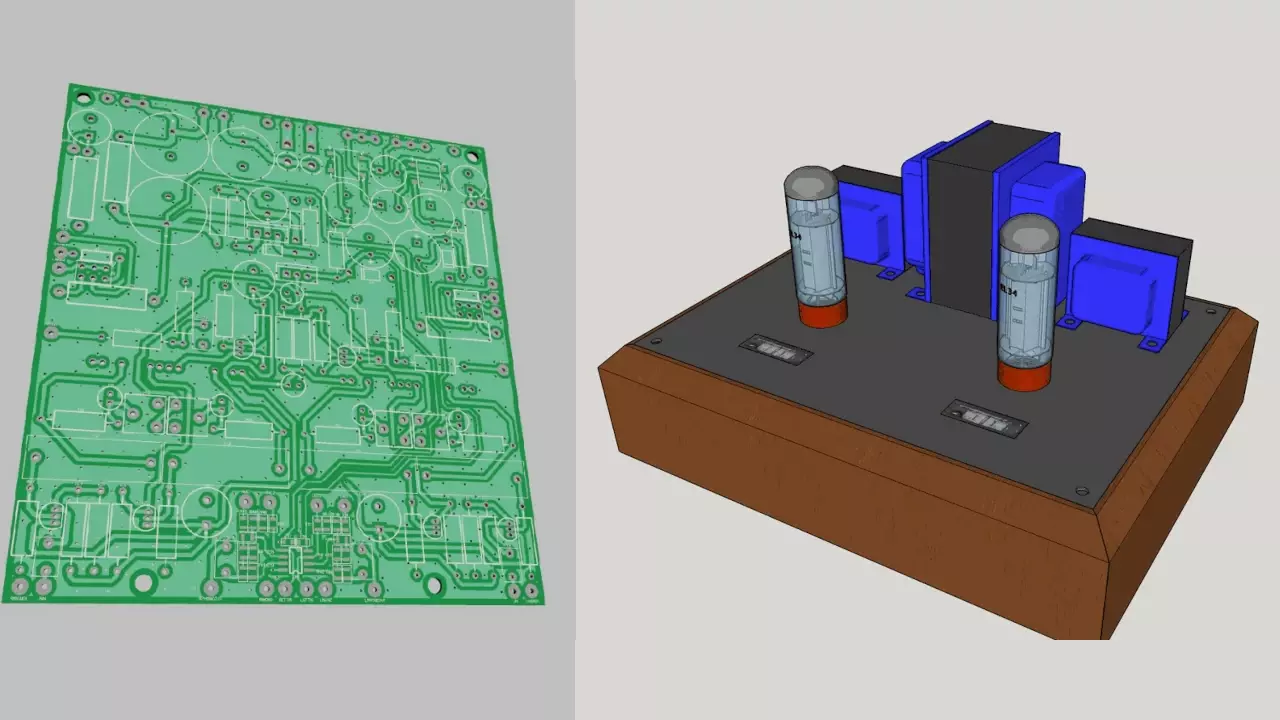

- The MacroAmp’s PCB has been completed. Stephen ordered the PCB earlier this week. It is a 2 X 10W tube Hi-Fi stereo using Korg Nutubes as the preamp.

- The FCC is going to investigate why the RF noise floor in the US has risen in the past years. Parker thinks its the “cost reduction” of devices after being certified. Will this be good or bad for makers? Does import customers have to test devices now? On the plus side, energy harvesting the RF band is more viable!

- Parker, Stephen, and Dustin get in a rant about Vss/Vdd/Vcc notation for schematics and circuits and Parker offers a solution.

- The AeroScope is a wireless, ultra-portable oscilloscope that uses Bluetooth 4.1 LE to communicate to a phone or tablet for the screen. Would be useful for Maker style field work. 100Mhz, 500M/samples, +-40V input. Fairly typical specifications. Runs $260 on the crowd funding website.

Figure 1: The test fixture Stephen and Dustin have been working on. Talks to a python script Dustin wrote on the PC.

Figure 2: Front test panel for the SSPS. Code should be working shortly for it. Everything physically fit in the footprints!

Figure 3: MacroAmp Stephen is working on. 3D rendering done in SketchUp.

About the Hosts

Parker Dillmann

Parker is an Electrical Engineer with backgrounds in Embedded System Design and Digital Signal Processing. He got his start in 2005 by hacking Nintendo consoles into portable gaming units. The following year he designed and produced an Atari 2600 video mod to allow the Atari to display a crisp, RF fuzz free picture on newer TVs. Over a thousand Atari video mods where produced by Parker from 2006 to 2011 and the mod is still made by other enthusiasts in the Atari community.

In 2006, Parker enrolled at The University of Texas at Austin as a Petroleum Engineer. After realizing electronics was his passion he switched majors in 2007 to Electrical and Computer Engineering. Following his previous background in making the Atari 2600 video mod, Parker decided to take more board layout classes and circuit design classes. Other areas of study include robotics, microcontroller theory and design, FPGA development with VHDL and Verilog, and image and signal processing with DSPs. In 2010, Parker won a Ti sponsored Launchpad programming and design contest that was held by the IEEE CS chapter at the University. Parker graduated with a BS in Electrical and Computer Engineering in the Spring of 2012.

In the Summer of 2012, Parker was hired on as an Electrical Engineer at Dynamic Perception to design and prototype new electronic products. Here, Parker learned about full product development cycles and honed his board layout skills. Seeing the difficulties in managing operations and FCC/CE compliance testing, Parker thought there had to be a better way for small electronic companies to get their product out in customer's hands.

Parker also runs the blog, longhornengineer.com, where he posts his personal projects, technical guides, and appnotes about board layout design and components.

Stephen Kraig

Stephen Kraig is a component engineer working in the aerospace industry. He has applied his electrical engineering knowledge in a variety of contexts previously, including oil and gas, contract manufacturing, audio electronic repair, and synthesizer design. A graduate of Texas A&M, Stephen has lived his adult life in the Houston, TX, and Denver, CO, areas.

Stephen has never said no to a project. From building guitar amps (starting when he was 17) to designing and building his own CNC table to fine-tuning the mineral composition of the water he uses to brew beer, he thrives on testing, experimentation, and problem-solving. Tune into the podcast to learn more about the wacky stuff Stephen gets up to.

Special thanks to whixr over at Tymkrs for the intro and outro!

Related Podcasts

Wizard Trust Falls for PCB Footprints

Parker’s transition from Eagle to KiCad, facing challenges with library management and device layer integration. Also, the new MacroFab Quote Wizard.

How Soft Are Your Diodes?

Parker's pinball controller has gone gold! Revision 3 is being fabricated! Stephen then explores the softness factor of diodes and the SSPS returns?

The Toilet Mountain of Social Media

The hefty topic of U.S. funding for 'digital twin' chips research under the CHIPS Act, comparing its budget to other big expenditures.

Solder Slugs

We'll dive into nuances of working with contract manufacturers, specifically focusing on the responsibilities of both the designer and the manufacturer.

Screaming into the Social Media Void

AutoDesk is dropping support and development for the dedicated Eagle EDA tool and moving efforts to the AutoDesk Fusion 360 Electronics.

Viciously Different Creams

Does anyone actually use the metric sizing for chip components? The ole' 0603 metric and 0201 imperial chip component switcheroo on this episode.

About MacroFab

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.