MacroFab Blog

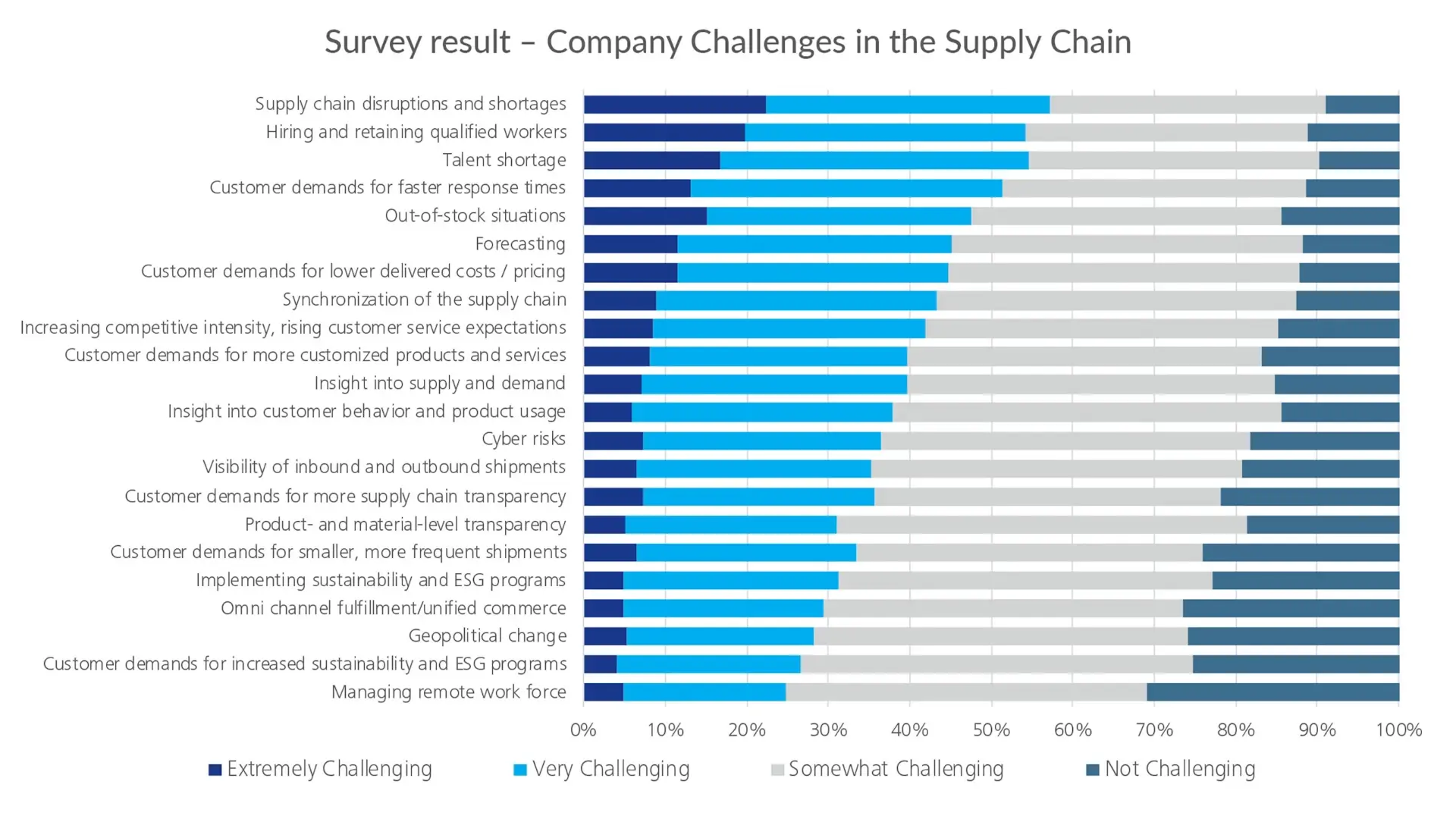

In the age of lightning-fast technological advancements, electronics companies are finding it increasingly difficult to keep up with the constant demand for their products. Their challenges are multifaceted and complex, ranging from supply chain disruptions and talent shortages to cyber risks and out-of-stock situations.

The supply chain’s lack of control and transparency, coupled with the competition for critical components and unpredictable economic changes, make it an uphill battle to meet revenue targets, maintain consistent quality, and deliver on time. In this blog, we will delve deeper into the most significant supply chain challenges facing electronics companies and explore the impact on the quality outcomes of their products.

Supply Chain Disruptions and Shortages

Global supply chains have been significantly impacted by the pandemic and geopolitical events, resulting in a shortage of raw materials, products, and finished goods. This has created a need for greater transparency in shipments, product, and material-level tracking and forecasting, which is essential for electronics companies to keep up with customer demand.

However, the disruptions have caused a ripple effect, resulting in late shipments, manufacturing delays, and product quality issues.

Consequently, companies have missed their revenue targets, and end-users have become dissatisfied with the service they receive. It is crucial to address these issues and find ways to mitigate the disruption impacts to ensure business continuity and maintain customer satisfaction.

Hiring and Retaining Qualified Workers/Talent Shortages

Electronics companies need talented and skilled workers to develop, manufacture, and maintain their products. However, talent competition is fierce, with many companies vying for the same pool of skilled workers.

Additionally, high-turnover rates as employees switch jobs for better compensation and benefits remains a significant challenge. This lack of skilled workers can lead to quality issues in the manufacturing process, affecting the overall product quality. An IPC survey found that more than 70 percent of electronics manufacturers have reported a shortage of skilled workers. Similarly, in a survey by Robert Half Technology, 49 percent of IT managers said they lost an employee due to salary issues in 2022.

This scarcity of skilled labor can hinder a company’s ability to meet customer demand, causing delays in production and missing revenue targets.

According to a report by KPMG, a lack of talent is the number one challenge complicating the adoption of digital technologies. The shortage of IT professionals, especially in cybersecurity, is hampering innovation and growth for electronics companies.

Cyber Risks, Data Privacy/Security Issues

Checkpoint

Cyber risks, data breaches, and out-of-stock situations can cause severe damage to a company’s reputation and result in lost revenue.

In today’s digital age, electronics companies face new data privacy and security challenges. Cyber risks, data breaches, and out-of-stock situations can cause severe damage to a company’s reputation and result in lost revenue. The challenge of sometimes working with legacy systems only compounds the issue.

Legacy systems pose a challenge to maintaining customer data safety and cybersecurity for several reasons. Firstly, they may be incompatible with access security features, such as multi-factor authentication, single-sign-on, and role-based access. Secondly, they may lack sufficient audit trails or encryption methods, which is not in line with today’s security best practices. These systems may also store sensitive data that organizations no longer need, but if breached, can pose a risk.

Furthermore, older systems may be unprepared to handle a cyber incident because they lack the latest updates and tools. This can lead to more significant damage and put an organization’s reputation and revenue at risk. IBM Security and Ponemon Institute report for 2020 found that the average cost of a data breach globally was $3.86 million. Therefore, it is crucial to ensure that systems are up-to-date with the latest security features and tools to mitigate the risk of cyber incidents and data breaches.

Data is a crucial asset for companies and a common target of cyber-attacks within the supply chain. However, a survey conducted by Deloitte revealed that 55 percent of manufacturers do not have complete visibility into their supply chain, leaving them vulnerable to cyber risks and data privacy breaches.

The lack of visibility into the supply chain can result in manufacturers being unaware of potential weaknesses in their suppliers’ cybersecurity measures. This can lead to data leaks, supply chain breaches, and malware attacks. For instance, BlueVoyant, a cybersecurity company, found that 82 percent of organizations suffered a data breach in 2020 due to cybersecurity weaknesses within their supply chain.

To avoid these risks, it is essential to have full visibility into the supply chain and ensure that all suppliers have appropriate cybersecurity measures in place. This will reduce the likelihood of data breaches, supply chain breaches, and other cybersecurity threats.

Out-of-Stock Situations

For electronic companies, especially those relying on global supply chains, out-of-stock situations can be a significant problem. Severe weather conditions, port congestion, and transportation delays can lead to shortages of essential components and raw materials, resulting in production delays and missed revenue targets.

The global semiconductor shortage in 2021, for instance, led to significant disruptions in the electronics industry, costing the industry $121 billion in lost revenue, according to a report by Gartner. Transportation delays can also have a considerable impact on supply chain operations, with port congestion and delays costing up to $2 billion per month in 2021, according to a report by the National Retail Federation.

Effective supply chain management and contingency planning are crucial to mitigate the risks of out-of-stock situations and ensure business continuity for electronic companies. This requires investing in digital transformation and automation to improve operational efficiency and customer satisfaction. IDC predicts that global spending on digital transformation technologies will reach $2.3 trillion in 2023.

Moreover, according to a survey by MHI and Deloitte Consulting LLP, supply chain disruptions and shortages have become the top challenge in supply chain management, overtaking the issue of hiring and retaining skilled workers. This shift is due to the ongoing effects of the global pandemic. Therefore, electronic companies must adopt digital technologies to enhance the resilience of their supply chains and mitigate the impact of future disruptions.

Although talent concerns and customer demands remain significant challenges, addressing these issues is crucial to prevent future disruptions to the supply chain.

Sixty-three percent of electronics companies have experienced supply chain disruptions in the last few years. A lack of talent is the number one challenge complicating the adoption of digital technologies. Cyber risks, data breaches, and out-of-stock situations can cause severe damage to profits.

To ensure long-term success, companies must invest in technology and talent and implement robust security measures. This will enable them to meet customer demand, maintain quality, and safeguard sensitive data.

Related Topics

ITAR in Electronics Manufacturing: Maintaining Compliance

A discussion about ITAR and the shared responsibility in protecting essential technologies and services vital to the security of our nation.

Mapping Out a PCBA Supply Chain Strategy in Five Moves

Companies should create unique vendor relationships with numerous international suppliers due to the necessity of having to source components globally.

MacroFab’s Modern Approach to Strategic Sourcing

Many Contract Manufacturers (CMs) and Original Equipment Manufacturers (OEMs) have some sort of procurement team. So what makes MacroFab so different?

Build a Responsive, Flexible & Resilient Supply Chain That Actually Works

Learn how MacroFab can decrease your supply chain risk.

About MacroFab

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.