MacroFab Blog

The turmoil of the last few years, starting with the pandemic, has underscored the importance of digital procurement in electronics manufacturing. This sector is increasingly adopting AI, robotic process automation, and predictive analytics to enhance efficiency and manage costs. However, the epidemic also exposed the vulnerability of global supply chains.

A 2022 PwC survey revealed that while 93 percent of supply chain executives plan to improve their supply chains’ flexibility and resilience, only 92 percent have made physical changes, and a mere 2 percent have comprehensive visibility into their third-tier suppliers, where critical supply shortages often occur.

Despite these challenges, the shift towards digital procurement strategies in Printed Circuit Board Assembly (PCBA) manufacturing emerges as a strategic boon. These digital strategies enhance

operational efficiency, minimize costs, and maintain production continuity amidst global uncertainties. Most companies have invested in digital supply chain technologies, improving visibility and performance management systems, thereby boosting their resilience to supply chain disruptions.

The New Era of Digital Procurement

Digital procurement is the amalgamation of technology and procurement processes, leveraging tools like e-procurement platforms, Supplier Relationship Management (SRM) systems, procurement analytics, and collaboration software.

These tools aren’t merely supplementary but integral components reshaping the procurement landscape in electronics manufacturing. For example, McKinsey reports that companies with digital supply chains can expect efficiency improvements of 3.2 percent annually and procurement costs to decrease by 3.4 percent.

Automating manual tasks results in significant time savings and reduced error occurrence. The capability to assess and compare suppliers and products based on price and quality assures optimal cost management. Digital procurement tools streamline operations and create opportunities for strategic decision-making and cost savings.

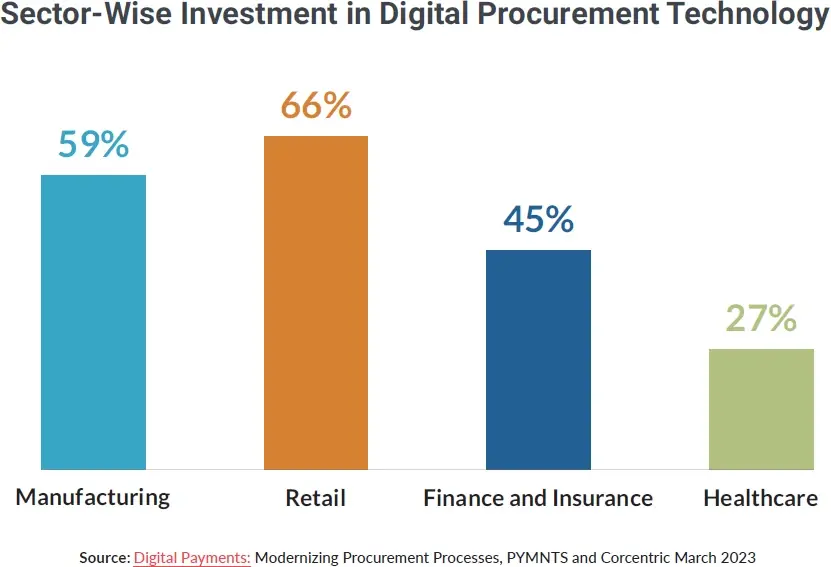

Digital Procurement Investment in Different Sectors

Across diverse industries, the trend toward modernization and efficiency through digital procurement technology is steadily on the rise. The manufacturing sector is at the forefront, with 59 percent of its companies harnessing digital procurement to streamline their operations. Not far behind is the retail sector, where 66 percent of companies are making similar investments to embrace the digital era. The finance and insurance sectors are catching up, with 45 percent of companies tapping into digital technology to revamp their procurement processes. The healthcare sector, although lagging, is also joining this digital revolution, with 27 percent of companies investing in digital procurement technology.

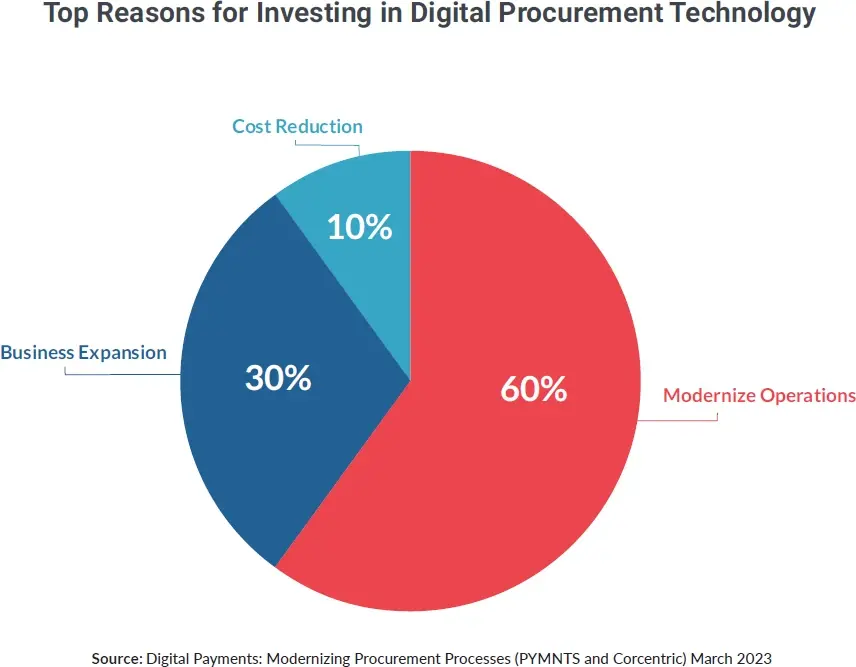

The Digital Payments report provides insights into the motivations propelling these investments. Companies primarily invest in digital procurement technology to modernize operations, broaden the business, and reduce costs. Healthcare companies and finance and insurance businesses emphasize business expansion. Cost reduction is a critical objective, with 21 percent of healthcare companies, 18 percent of finance and insurance companies, and 18 percent of manufacturers citing it as their top reason for investment.

The primary objectives of investing in digital procurement are modernizing operations, expanding business, and reducing costs. These goals are transforming procurement processes and reshaping the entire business landscape. By investing in digital procurement technology, companies are modernizing operations, preparing for growth, optimizing cost structures, and growing.

The rise in digital procurement investments across various sectors attests to its strategic benefits. As companies persist in modernizing, expanding, and reducing costs, digital procurement technology will undoubtedly play a crucial role in shaping global value chains’ future.

The Strategic Advantages of Digital Procurement in PCBA Manufacturing

Digital procurement offers substantial benefits, including improved speed and quality of procurement, risk reduction, and enhanced innovation. Companies that harness new tools for collaboration can reduce the time from purchase order to invoice, automating purchasing processes to free up time for strategic work.

Checkpoint

A fully automated procurement function could save substantial amounts for companies, with potential annual savings reaching up to $86 billion for the Global 5000.

Research indicates that a fully automated procurement function could save substantial amounts for companies, with potential annual savings reaching up to $86 billion for the Global 5000. For companies with a spending base of $1 billion to $3 billion, this translates to $12 million in annual procurement headcount savings. Those that spend $3 billion or more would save an average of $27 million on headcount.

Digital procurement technologies such as AI, Robotic Process Automation (RPA), blockchain, and IoT are increasingly prevalent in addressing long-term sourcing issues. These technologies enable real-time spend management, demand prediction using AI, calculating landed costs for commodities from all potential origins, predicting future supply sources, and timely response to alerts from negotiated agreements.

The benefits of digital procurement in electronics manufacturing are manifold. It streamlines procurement processes, enhances supplier relationship management, improves contract handling, and strengthens procurement analytics. Digital procurement enables strategic sourcing to become predictive, transactional procurement to be automated, and supplier risk management to be proactive, leading to more efficient operations and cost savings.

Notably, digitization has also facilitated the transition to remote working. Despite initial challenges, companies have managed this transition effectively, with 58 percent reporting satisfactory supply-chain-planning performance over the past year.

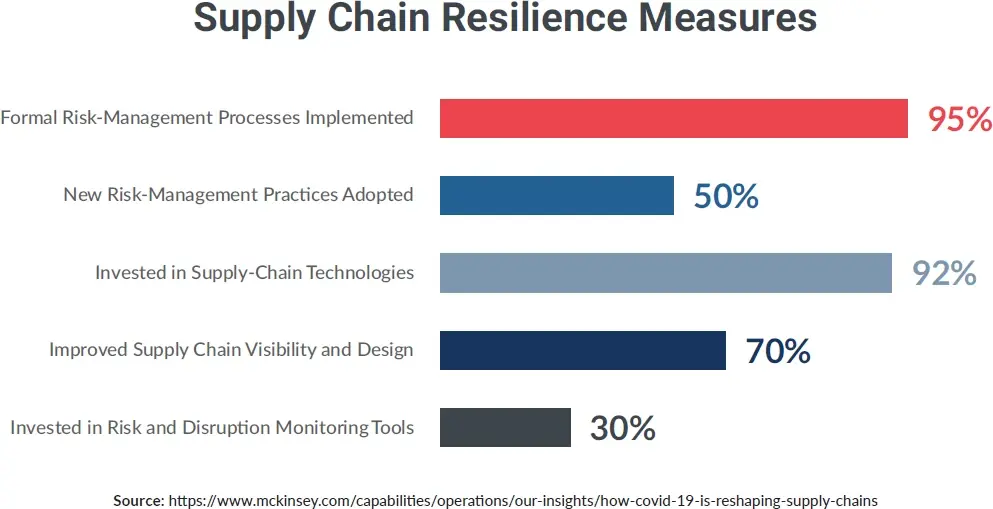

Future-proofing is a crucial aspect of digital procurement. The pandemic has catapulted risk to the top of the corporate agenda, with 95 percent of firms implementing formal supply-chain risk-management processes. Over half of these firms have adopted new supply-chain risk management practices, enhancing their resilience and agility to disruptions.

Furthermore, most firms have invested in digital supply-chain technologies over the past year, with many investing more than initially planned. These investments will continue, focusing on improving supply chain visibility and design. However, only a minority of firms invest in tools to monitor risks and disruptions, indicating a significant area for future growth and development.

Digital procurement provides strategic advantages in PCBA manufacturing by fortifying supply chain management, streamlining processes, improving supplier relationships, and enhancing procurement analytics. It also empowers companies to be more resilient and responsive to market shifts, marking it as a vital tool for future-proofing operations.

Conclusion

Digital procurement has emerged as an essential tool in the electronics manufacturing industry, particularly in mitigating challenges posed by the COVID-19 pandemic. This transition to digitization, driven by AI, robotic process automation, and predictive analytics, boosts operational efficiency, cost control, and resilience amidst global uncertainties. It is, however, necessary to invest in talent acquisition and reskilling in order to unlock the full potential of digital procurement.

In today’s business landscape, OEM procurement teams must adopt digital procurement to gain a competitive edge. It’s a strategic necessity for modernization, cost reduction, business expansion, and supply chain resilience.

Procurement leaders should contemplate significant investments in digital procurement technologies. This will enable their organizations to better navigate the intricacies of global supply chains, enabling them to seize new opportunities in the digital age.

Related Topics

Mapping Out a PCBA Supply Chain Strategy in Five Moves

Companies should create unique vendor relationships with numerous international suppliers due to the necessity of having to source components globally.

MacroFab’s Modern Approach to Strategic Sourcing

Many Contract Manufacturers (CMs) and Original Equipment Manufacturers (OEMs) have some sort of procurement team. So what makes MacroFab so different?

Electronics Production: Upgrading Inventory Systems with Modern Tech

Inventory and supply chain management software and processes play a pivotal role in safety, efficiency, & security of electronics manufacturing operations.

Make Procurement Easier with MacroFab

See MacroFab's Procurement Services NowAbout MacroFab

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.