MacroFab Blog

The assembly manufacturing process, including solder flux, has a large impact on the success of final product quality.

The assembly manufacturing process, including solder flux, has a large impact on the success of final product quality. A robust surface mount assembly maintains high reliability over the life of the product, and the soldering process and type of flux used are key contributing factors to surface mount technology (SMT) assembly success. Let’s review how to use flux during soldering and how to decide which technology and contract manufacturing (CM) partner to choose.

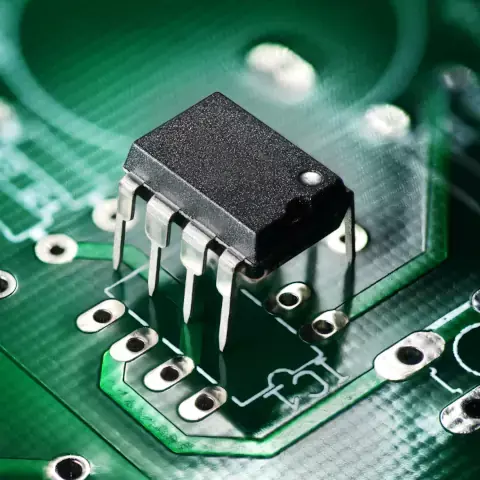

Soldering is the primary technique used within electronics manufacturing to electrically attach components to a printed circuit board (PCB). Soldering involves melting metal conductive material across masked metal pads. This forms electrical connections between the PCB and components called solder joints.

Checkpoint

Flux methods need tight process control to ensure they work as intended without compromising soldering joint integrity.

The soldering process requires a special type of agent called flux. The physical properties of solder flux can vary significantly from type to type. Flux removes oxides that form as metal gets exposed to air; oxides prevent the formation of good solder joints between the two oxidized metals.

What is Solder Flux?

Soldering, the process of attaching electronic components to a printed circuit board (PCB), is a fundamental step in electronics manufacturing. To achieve a strong, reliable bond, a special chemical agent called solder flux is required. But what exactly is solder flux and what role does it play?

Simply put, solder flux is a powerful cleaning agent that removes impurities and oxidation from the surface of the PCB and component metal pins prior to soldering. This is essential for achieving a proper solder joint and preventing corrosion between the two metals.

Without proper flux cleaning, the solder won't properly adhere to the components or the PCB, leading to weak and unreliable joints. But choosing the right type of flux and application method is equally important to ensure a high-quality, long-lasting bond.

What Does Solder Flux Do?

Flux is critical in the creation of solder joint formation. During the soldering process, metallic impurities from both the solder and PCB fabrication can be present. Flux is used to eliminate these impurities from the PCB soldering surface, as well as to remove any oxides from the exposed metal surfaces.

After cleaning, flux presents a clean surface for a high-integrity solder joint. Once the flux has cleaned the surfaces, it prepares a clean area for a strong solder joint. However, after the soldering process is complete, the leftover residue needs to be cleaned through a final step. The specific cleaning method will depend on the type of flux used.

Flux is a mixture of an activating chemical and a base material. It is the activator that removes oxides from metal and promotes better solder wetting. Depending upon the final system use application, different types of flux types may lend to a more successful manufacturing outcome.

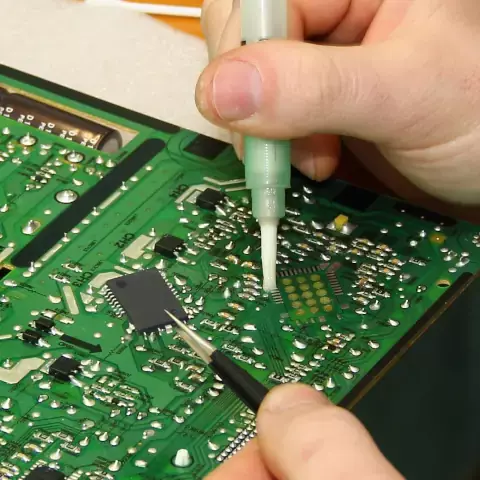

Flux Application Methods

Flux is often applied in one of these three methods. Each category has different chemical properties based upon component and board soldering requirements.

- Wave Soldering: Wave solder flux composition includes many solvents. Flux gets sprayed onto the PCB before the solder wave. The flux cleans the components and removes oxidation. Depending upon the prior manufacturing steps, the PCB may need pre-cleaning.

- Solder Reflow: Solder paste screened onto the PCB only targets the intended metal pads for connection to components. The paste holds the parts in place for a short duration until the oven heat causes the solder paste to reflow and adheres between the PCB and the component leads. Solder reflow cleans metal surfaces while the sticky flux prevents more oxidation. This type of paste flux contains additives to improve solder flow as it melts.

- Selective Solder: In this case, the flux targets specific areas of the PCB through a spray application or a precise drop jet process.

Cleaning Different Flux Types

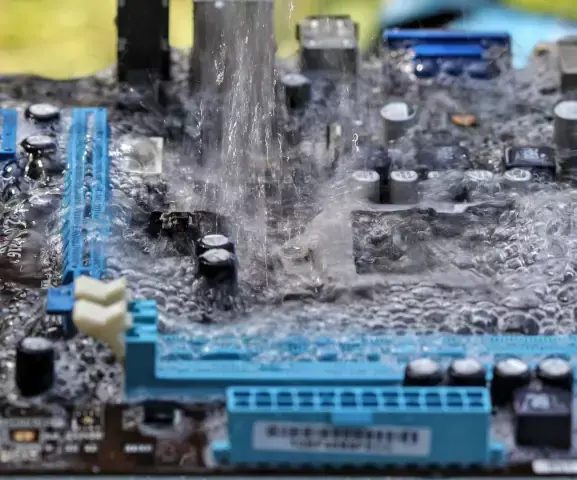

Fluxes can have corrosive properties; if residue remains, it can affect board performance months or years later. Don’t forget to clean the solder flux off circuit boards.

There are three primary flux types that have different manufacturing processes and cleaning requirements:

- Rosin-Based: This flux gets cleaned off the finished PCB with specific chemical solvents that often involve fluorocarbons. Most countries have restrictions on how to use this type of flux and the disposal of its chemical byproducts. As such, this older flux type is often rejected for either of the more favorable options.

- Water-Soluble: There are several cleaning agents that are more environmentally friendly that can be used for water-soluble fluxes. These options include deionized water and simple detergents.

- No-clean: No-clean fluxes need little to no cleaning after application. Instead, cleaning is more to improve appearance than to prevent imperfections, as residue rarely leads to any contamination. But sensitive electronic and optical inspection equipment can experience some failures, and no-clean fluxes can interfere with testing and conformal coating. Thus, cleaning is still recommended.

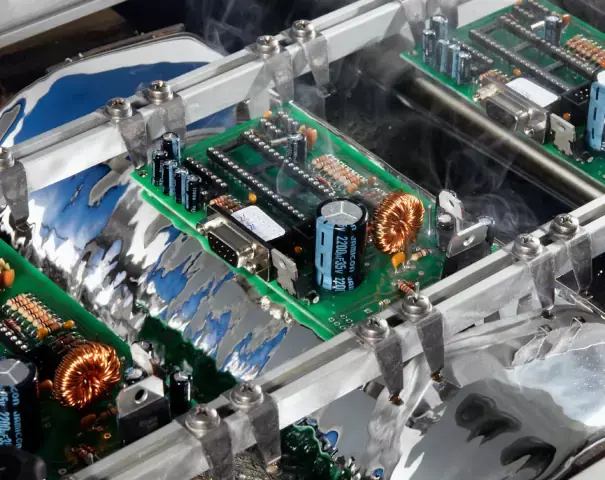

All three of these methods need tight process controls to make sure that the flux works as intended without compromising soldering joint integrity. If not properly controlled, heated solvents have the potential to outgas and form a void within a solder joint.

Another quality problem could involve molten solder splattered onto unintended areas of the board that should get masked from solder. You can read more about solder mask in our article about SMD vs NSMD.

Choosing the right solder flux will depend upon your application, customer use, and the complexity of the component layout. By working with your CM during the design process, they can help guide you in the best solder flux manufacturing processes for your solution. MacroFab offers only no-clean and water-soluble fluxes.

Other Common Questions about Solder Flux

Do You Need Flux to Solder?

The simple answer is yes, you absolutely need flux when soldering. Flux serves a critical role in creating clean, reliable solder joints by removing oxides and impurities from the metal surface you're connecting. These contaminants can inhibit the solder's ability to wet the surfaces effectively, leading to weak or unreliable connections.

From a professional standpoint, flux use becomes even more crucial in large-scale production. Clean, robust solder joints are essential for maintaining product reliability, and this is where flux shines. Additionally, certain types of soldering, such as surface-mount soldering or reflow soldering, practically demand flux usage due to the precision required.

If you're working on boards one by one, using flux can help enhance your soldering accuracy and result in more durable and reliable circuits. It can be particularly beneficial if you're working with older or more oxidized components.

What is Solder Flux Made Of?

Solder flux typically consists of rosin (derived from pine sap), but manufacturers often blend it with other chemicals to enhance its performance. These additions can include activators, such as acids or amine halides, which increase the flux's ability to remove oxides. In some cases, they add solvents to make the flux more spreadable.

Professional-grade flux often features more complex blends of chemicals designed to optimize performance under specific conditions. These fluxes may also need to meet particular standards, such as those set by the IPC (Association Connecting Electronics Industries), ensuring consistent performance across different manufacturing environments.

Can Solder Flux Go Bad?

Generally, solder flux has a long shelf life, but it can degrade over time, particularly under improper storage conditions. Exposure to heat, light, or moisture may hasten this process. It's always essential to check the manufacturer's specifications for an exact shelf life and storage conditions.

For a professional setting where bulk quantities of flux are often in use, maintaining optimal storage conditions becomes more critical to avoid waste and maintain soldering quality.

For individuals, it's important to keep in mind that an opened container of flux will likely degrade faster due to exposure to air. Replacing your flux periodically and keeping it sealed when not in use will ensure you always have high-quality flux on hand.

Conclusion

Selecting a CM that follows your guidance on soldering processes is important. Not only will environmental policies in the country of origin impact your decisions, but also your customers will have an impact. Strict requirements imposed by some customers on the solder application and cleaning methods of flux will dictate manufacturing compliance. In addition, economic regions such as the European Union have banned the use of lead within solder and flux for all new electronics solutions.

About MacroFab

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.