Related Topics

Repairing the Retro Future

This week we dive into the fascinating world of vintage tech repair, focusing on efforts to preserve General Motors' futuristic '80s digital displays.

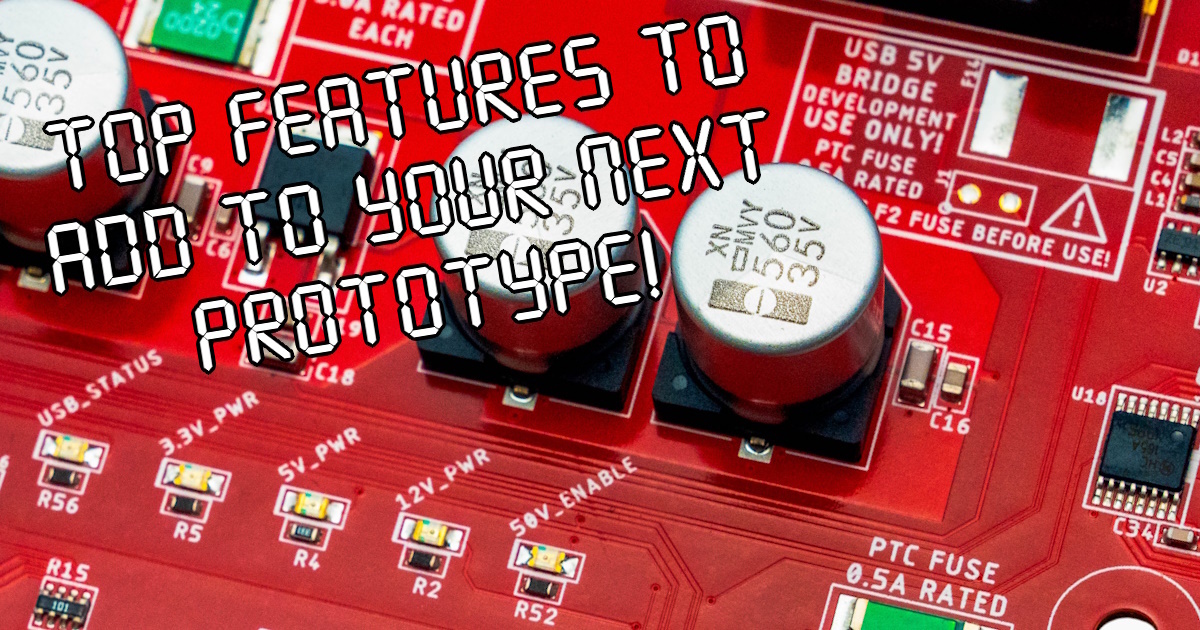

Top Features to Add to Your Next Prototype

Tune in as we share insights, anecdotes, and maybe a few confessions from our own prototyping adventures.

Perpetual Prototypes

Did Stephen and Parker complete there holiday projects as mentioned in last weeks episode or will they slip further behind with feature creep?

Other Resources

Circuit Break Podcast

Webinars

Videos

Tour MacroFab's ITAR-Compliant Facility

October 7, 2020, Episode #245

Parker

- Security flaw left ‘smart’ chastity sex toy users at risk of permanent lock-in

- List to podcast for additional information…

Stephen

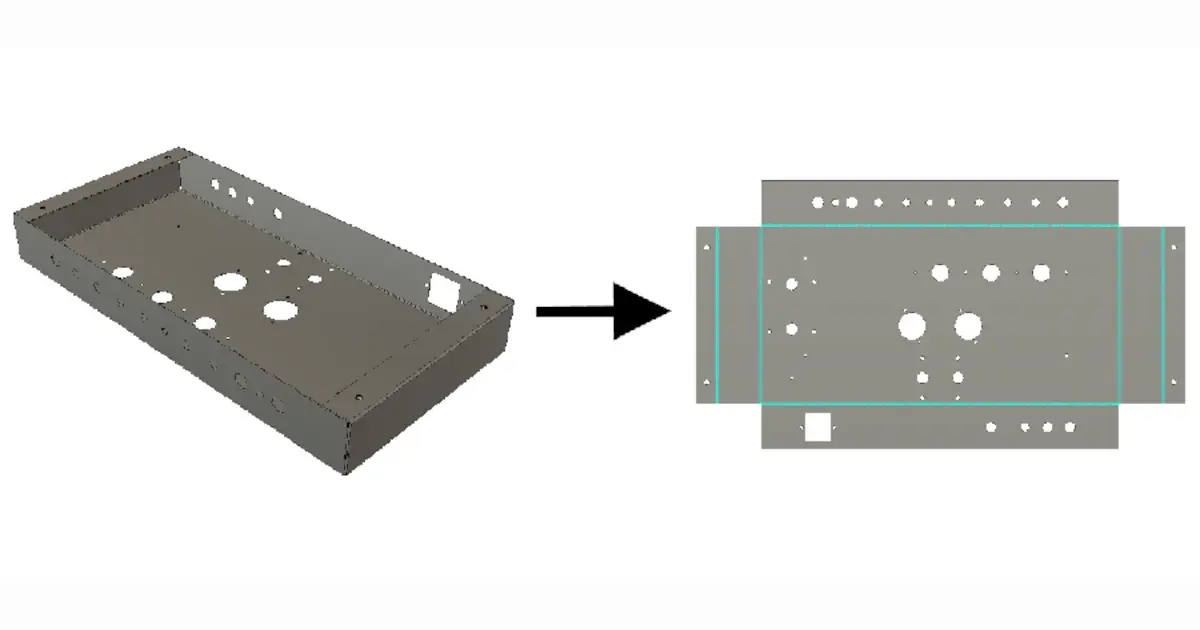

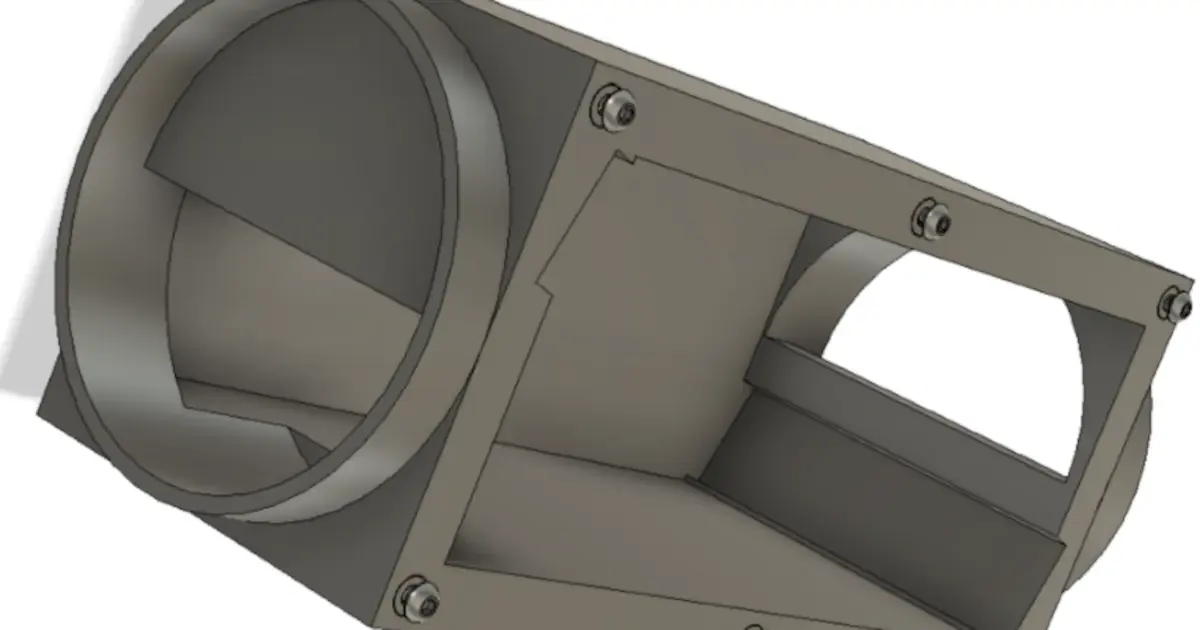

- Fusion 360 has changed their personal license subscription model

- All of these went into effect on Oct 1

- Project storage is limited to 10 active and editable documents

- Exports are now limited to a small number of file types. Thankfully this still includes STL files but alas, DXF, DWG, PDF exports are all gone

- Perhaps most importantly to the makerverse, STEP, SAT, and IGES file types can no longer be exported, the most common files for those who want to edit a design using different software.

- 2D drawings can now only be single sheet, and can only be printed or plotted

- Rendering can now only be done locally, so leveraging cloud-based rendering is no longer possible

- CAM support has been drastically cut back: no more multi-axis milling, probing, automatic tool changes, or rapid feeds, but support for 2, 2.5, and 3 axis remains

- All support for simulation, generative design, and custom extensions has been removed

- Purchased a license and I am not looking back

- Autodesk had loads of pushback from the community because of the decision to remove STEP export

- “Fixed” this issue claiming the reversal was due to “unintended consequences for the hobbyist community.”

- All of these went into effect on Oct 1

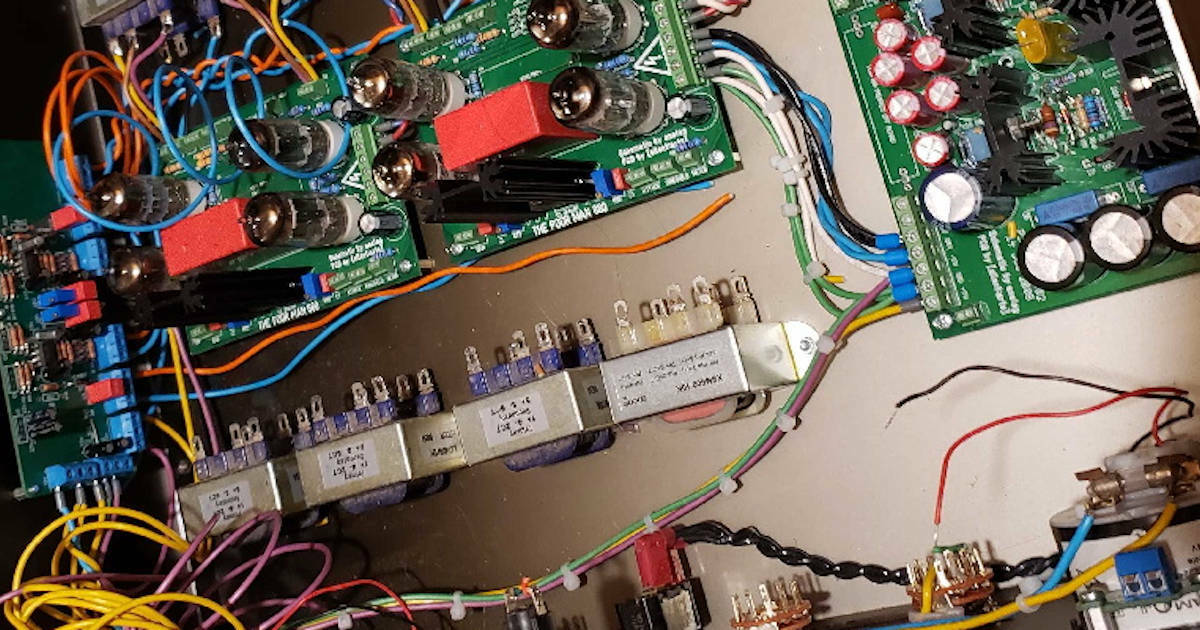

- Sheet metal design and fabrication

- Be careful with using automated tools

- Understand the rules

- Dont rely entirely on templates

- As always – talk with your manufacturer

About the Hosts

Parker Dillmann

Parker is an Electrical Engineer with backgrounds in Embedded System Design and Digital Signal Processing. He got his start in 2005 by hacking Nintendo consoles into portable gaming units. The following year he designed and produced an Atari 2600 video mod to allow the Atari to display a crisp, RF fuzz free picture on newer TVs. Over a thousand Atari video mods where produced by Parker from 2006 to 2011 and the mod is still made by other enthusiasts in the Atari community.

In 2006, Parker enrolled at The University of Texas at Austin as a Petroleum Engineer. After realizing electronics was his passion he switched majors in 2007 to Electrical and Computer Engineering. Following his previous background in making the Atari 2600 video mod, Parker decided to take more board layout classes and circuit design classes. Other areas of study include robotics, microcontroller theory and design, FPGA development with VHDL and Verilog, and image and signal processing with DSPs. In 2010, Parker won a Ti sponsored Launchpad programming and design contest that was held by the IEEE CS chapter at the University. Parker graduated with a BS in Electrical and Computer Engineering in the Spring of 2012.

In the Summer of 2012, Parker was hired on as an Electrical Engineer at Dynamic Perception to design and prototype new electronic products. Here, Parker learned about full product development cycles and honed his board layout skills. Seeing the difficulties in managing operations and FCC/CE compliance testing, Parker thought there had to be a better way for small electronic companies to get their product out in customer's hands.

Parker also runs the blog, longhornengineer.com, where he posts his personal projects, technical guides, and appnotes about board layout design and components.

Stephen Kraig

Stephen Kraig is a component engineer working in the aerospace industry. He has applied his electrical engineering knowledge in a variety of contexts previously, including oil and gas, contract manufacturing, audio electronic repair, and synthesizer design. A graduate of Texas A&M, Stephen has lived his adult life in the Houston, TX, and Denver, CO, areas.

Stephen has never said no to a project. From building guitar amps (starting when he was 17) to designing and building his own CNC table to fine-tuning the mineral composition of the water he uses to brew beer, he thrives on testing, experimentation, and problem-solving. Tune into the podcast to learn more about the wacky stuff Stephen gets up to.

Special thanks to whixr over at Tymkrs for the intro and outro!

Related Podcasts

Perpetual Prototypes

Did Stephen and Parker complete there holiday projects as mentioned in last weeks episode or will they slip further behind with feature creep?

My CNC Will Melt In Your Mouth

Learning Autodesk Fusion, Braze it 420, and Stephen's CNC machine rise from its disassembled grave on this weeks episode of the podcast.

Repairing the Retro Future

This week we dive into the fascinating world of vintage tech repair, focusing on efforts to preserve General Motors' futuristic '80s digital displays.

Get Cute This Weekend

The Brewery LIVES! Parker turns on his electric brewery for the first time! Tips and tricks about homebrewing on this episode of the MacroFab Podcast!

Benjamin Jordan of Autodesk

Senior Product Manager for ECAD in Autodesk Fusion 360, Ben Jordan, joins Stephen and Parker to discus the future of ECAD, Eagle, Autodesk, and PCBs.

Top Features to Add to Your Next Prototype

Tune in as we share insights, anecdotes, and maybe a few confessions from our own prototyping adventures.

About MacroFab

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.