MacroFab Blog

Partner With One, Have Access to Many

Checkpoint

Multi-sourcing reduces your company’s risk exposure but can create more operational complexity.

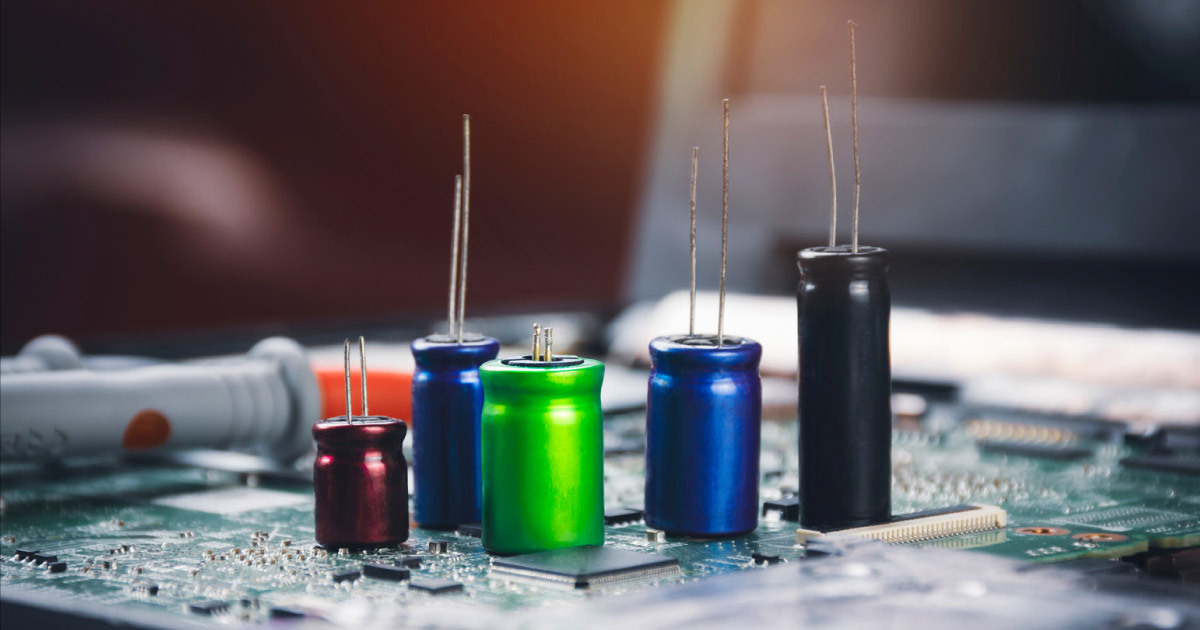

Our supply chains are more complex than ever, as are the products we create. Also, our deeply intertwined supplier networks span the entire globe. It’s only getting harder for procurement teams to avoid disruption and meet timelines and customer demands.

The COVID-19 pandemic revealed the fragility of our supply chains. As a result, those who relied on single sourcing found themselves struggling to keep their production lines running. Today’s supply managers now look to multi-sourcing strategies to maintain production timelines and quality. But the complexity of working with many vendors can prove difficult and time-consuming. Fortunately, multi-sourcing has gotten easier, so long as teams have the right tools and processes in place.

Multi-sourcing vs. Single-sourcing

Single sourcing refers to purchasing a specific resource or product from one supplier. It’s been the go-to strategy for many companies over the last several decades. When executed well during stable times, single sourcing can be an effective approach to supply chain management. But in today’s marketplace, single sourcing can add unnecessary roadblocks.

In theory, single sourcing allows brands to unlock economies of scale by consolidating purchasing volumes with one vendor. It enables procurement teams to build long-term relationships with one partner they trust to deliver on commitments year after year. Through this long-term relationship, leaders optimize for things like:

- Service quality

- Costs

- Payment terms

- Design validation and production validation testing

- Engineering change order processes

But this strategy ties your success to an outside relationship. This can expose you to losses if your partner company experiences a disruption for any reason. And if your partner becomes overloaded with orders from a more important customer, your needs may get put on the back burner.

Multi-sourcing is all about spreading the risk. Through multisourcing, companies buy the same resource or product from several suppliers. Multi-sourcing builds in

- Additional flexibility to cope with unexpected shifts that can jeopardize supply

- A safety net if one supplier experiences local difficulties

- Fewer bottlenecks when trying to meet peak demand

Advantages of Multi-sourcing

Multi-sourcing has clear advantages over single-sourcing. Sourcing from many suppliers gives you access to more overall supply. You also have more vendors to choose from to meet your needs when developing complex products.

Most importantly, multi-sourcing reduces exposure to disruption. Companies aren’t overly dependent on the financial success or capabilities of one vendor. This eliminates single points of failure and operational bottlenecks that would otherwise compromise production.

However, multi-sourcing can create more operational complexity. Supply chain managers have to deal with more relationships and communication channels. Data-sharing is harder, as getting all vendors on one integrated system is unlikely. Moreover, achieving economies of scale can be difficult when spreading buying across suppliers. And with so many facilities to visit, quality control can become a challenge.

How MacroFab Can Help

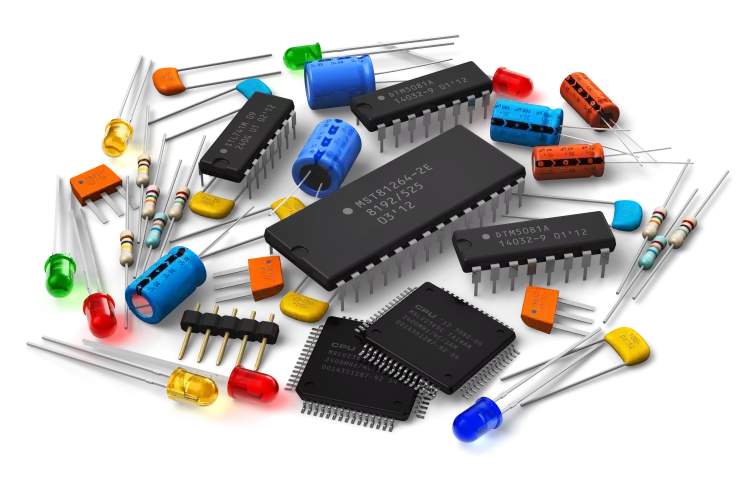

MacroFab can minimize the disadvantages of traditional sourcing models without requiring massive internal digital transformation, by serving as the front-end gateway to a vast vetted network of electronics suppliers. You get to focus on moving new products to market while MacroFab determines the safest, fastest, and most economical choice for each BOM item, keeping your timelines on track. And since MacroFab does high-volume business with many distributors, you have ‘economy of scale’ buying power behind your purchases.

Additionally, MacroFab’s digital platform centralizes the data you need to make informed decisions about sourcing critical products. Keeping records in a secure digital location where all stakeholders have access to them streamlines and improves the prototyping to production process.

MacroFab bom tool

By using MacroFab as your multi-sourcing partner, you take advantage of both single-sourcing and multi-sourcing strengths, combining advantages like

- A single, strong relationship with a trusted partner

- Access to a vast supplier network that limits risk and critical failure points

- Flexibility to meet demand and the maneuverability to avoid bottlenecks

- Bulk buying power without the bulk buying requirements

- Simple information sharing

With MacroFab, you can upload your BOM into our platform and immediately have access to pricing information from many sources.

Turnkey Kitting, Consignment, and Inventory Options

MacroFab offers additional procurement options, including turnkey kitting to reduce the complexity of your order. This service manages everything from board fabrication, BOM logistics, PCB assembly, QC, box build assembly and packaging, and drop ship to your customers. Plus we have an internal strategic sourcing team that rivals some of the best in the industry. Additionally, we can manage components already in your possession through consignment for a single order, or inventory for repeated orders.

The takeaway: use MacroFab to simplify your component sourcing. Platform users can diversify their supply chains without sacrificing cost or quality. Give your team more time to focus on designing, forecasting, and planning your final system by delegating time-consuming logistics to MacroFab.

Related Topics

Mapping Out a PCBA Supply Chain Strategy in Five Moves

Companies should create unique vendor relationships with numerous international suppliers due to the necessity of having to source components globally.

MacroFab’s Modern Approach to Strategic Sourcing

Many Contract Manufacturers (CMs) and Original Equipment Manufacturers (OEMs) have some sort of procurement team. So what makes MacroFab so different?

Electronics Production: Upgrading Inventory Systems with Modern Tech

Inventory and supply chain management software and processes play a pivotal role in safety, efficiency, & security of electronics manufacturing operations.

About MacroFab

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.