Overview

When a world-renowned power tool company realized its existing manufacturer had deprioritized jobs due to fluctuating demand, MacroFab offered them more flexible manufacturing options.

Regardless of volume, MacroFab's flexible approach provides high-quality service and timely production to meet the power tool company’s immediate needs.

Get to Know the Work

The international power tool manufacturer serves a variety of industries including the construction, aerospace, and electronics markets. The company works with distributors worldwide and has manufacturing facilities on five continents. Today, they operate in over 30 countries and generate $1.3B in revenue each year.

Assessment

In late 2020, the power tool company realized it needed to find a new contract manufacturer for its electronics group. The department’s engineering needs weren’t being prioritized by their existing manufacturer as the production facility wanted more volume commitment than the business actually needed. The tool company kicked off a search for a more flexible electronics manufacturing partner that could pick up production quickly, provide hands-on support, and grow with the electronics group.

Around the same time, a new electrical engineer joined the electronics group from another company. Formerly, the electrical engineer encountered MacroFab, an all-in-one digital platform streamlining every step of the electronics manufacturing process from PCBA manufacturing to full product assembly. Recognizing MacroFab’s unique business model would work well for the international tool manufacturer, the engineer made an introduction.

Challenge

Before coming to MacroFab, the company’s electronics group was working with a Taiwanese contract manufacturer happy to take on its electronics production needs, assuming the company could commit enough volume. However, the tool manufacturer had fluctuating demand and could not meet its original volume projections, leading the factory to focus on other relationships.

Adding complexity to the situation, the tool manufacturer was also revamping its electronics engineering discipline and trying to improve and standardize workflows from prototype to production. To accomplish this, however, the electronics group would need to find a manufacturing partner that could provide a high-touch relationship and an open line of communication.

The combination of falling short of original volume estimates and the high-needs nature of the electronics department made it hard for the company to get the services it needed from its Taiwanese manufacturer. The partnership wasn’t sustainable, and both sides knew it.

Process

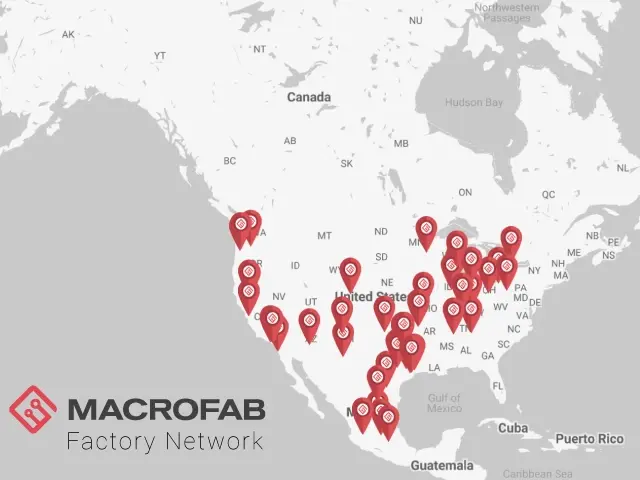

MacroFab works with a vast network of electronics manufacturing facilities across North America, all of which have been thoroughly vetted and categorized according to their capabilities. When companies work with MacroFab, they can tap immediately into this network without contracting with or evaluating any facilities themselves.

Instead, they can upload and iterate on designs directly in the platform and then choose where they get produced across MacroFab’s network. MacroFab will also make recommendations based on the design and identify alternative components when certain parts are unavailable.

MacroFab appealed to the tool manufacturer’s electronics group because the platform offered complete flexibility with production volume. Companies can make ultra-low and large-scale orders through MacroFab, which will then find the best factories for specific jobs based on many factors.

Our Solution

MacroFab can now ramp up production on other in-network factory lines or shift volume altogether to locations with higher volume capabilities without sacrificing quality or reliability, giving the electronics group the ability to scale quickly when necessary.

MacroFab has insight into what facilities are optimized for smaller pilot runs and prototyping, so the international tool company doesn’t have to worry about getting “fired” by tier 1 or tier 2 manufacturers without the capacity or interest to develop prototypes.

The electronics group also doesn’t ever have to conduct research to find factories with true electronics expertise. MacroFab does this internally, matching unique designs to individual facilities, and ensures companies can take advantage of the best manufacturing capabilities available.

Recognizing these benefits, the company’s electronics group began moving production away from its Taiwanese manufacturer to MacroFab’s North American network in late 2020.

Summary

Today, MacroFab fulfills 3 SKUs for the international tool manufacturer’s electronics group, totaling close to 200k total units. When the company is interested in prototyping a new design, MacroFab sets the company up with a U.S.-based facility equipped for rapid pilot runs. Once a design is perfected, MacroFab seamlessly moves its production to more cost-effective Mexico-based manufacturers.

Under this arrangement, the company has maximum flexibility when committing to production volumes and making change orders. It also has better insight into what’s happening in the marketplace because MacroFab will notify when key changes occur that could affect production, as well as offer suggestions for how to navigate those disruptions.

Looking ahead, the tool manufacturer and MacroFab plan to expand the relationship and collaborate on more product SKUs as the company shifts further away from its original Taiwanese manufacturer.