Now With Multi-Layer and PCB Customization!

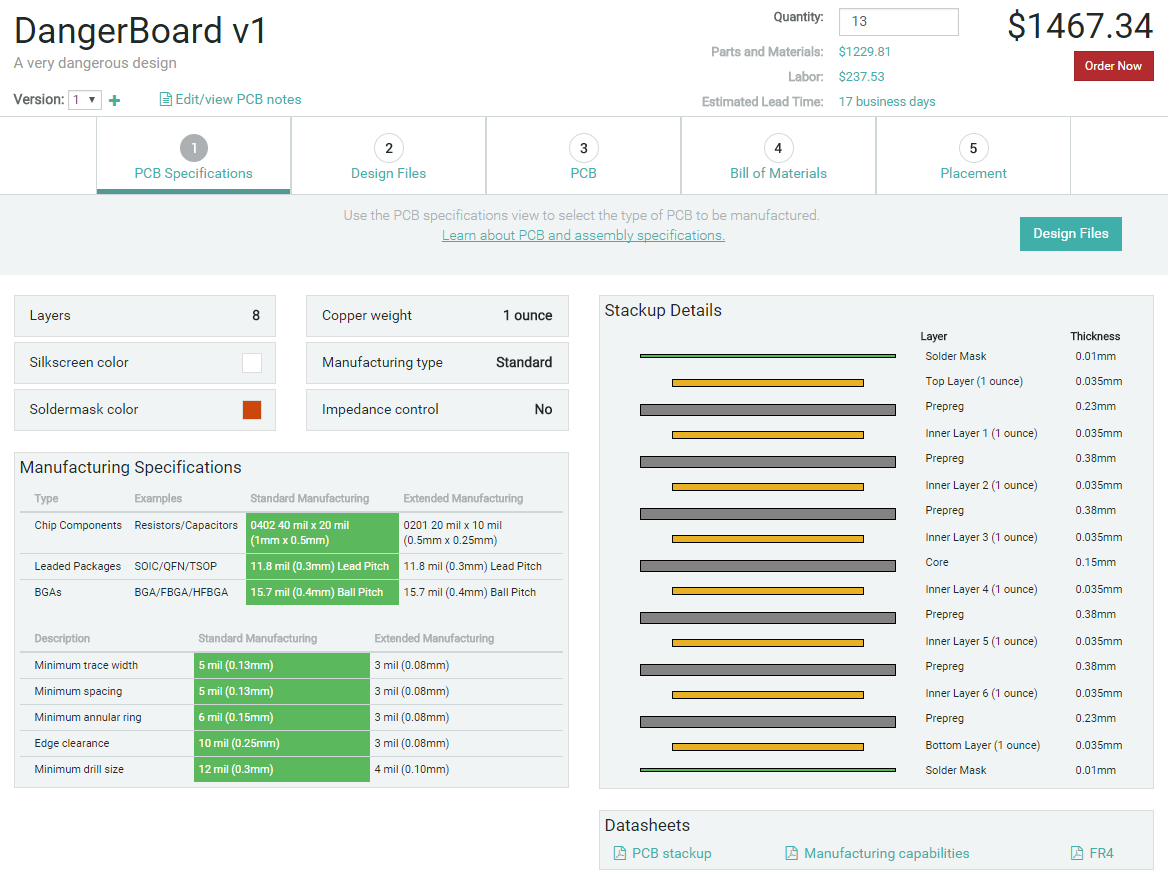

We’re pleased to announce our next big feature release: support for multi-layer boards and customized PCB options. With this software update, you now have the ability to control exactly how your PCBs look and what specifications are needed to produce the product you’ve been working so hard on.

New Options, Same Great Savings

Our standard PCB options for 2 and 4 layer work the same way they always have — we panelize your design with other designs that optimally work together for assembly, and you pay only your share of the overall materials and labor costs. However, if you need 6-8 layers, want to specify silkscreen and soldermask colors, or if you need a 2-oz copper pour you can now select those options and get your own panel run through our processes with low minimum charges.

For most of our existing customers, you’ll also see a reduced PCB cost by an average of about 10% for low-volume orders. As an added bonus, we’ve increased the standard PCB manufacturing specification, going to down to 5 mils (0.13mm) trace width and spacing. Our extended manufacturing specifications allow you to utilize 3 mil (0.08mm) trace width and spacing, and 4 mil (0.1mm) minimum drill size.

With these new features, you won’t need to contact support to handle custom PCB board needs, freeing your time for other more important things* by getting real-time pricing on complex board features.

Find out how MacroFab can handle your 4 layer PCB boards and many other options now.

From Beta to the Factory

After a lot of internal discussion, we decided that it was time to move from beta, so you’ll see a domain name change in the URL used to access our application. It will go from beta.macrofab.net to factory.macrofab.com. If you’ve got the old URL bookmarked, no worries! You’ll be automatically redirected to the new domain.

We’re always interested in how you use our service and what we can do to make the experience better for you. If you have suggestions, feature requests, or feedback, don’t hesitate to let us know by emailing us at support@macrofab.com

See how the MacroFab PCBA manufacturing process works.

Related Topics

Streamlined Mechanical BOM Management

Manage Mechanical Bills of Materials (MBOMs) with electrical BOMs in MacroFab's PCB platform. Streamline projects and save time with our new MBOM feature.

MacroFab's Bare PCB Option Helps You Develop Products Faster

We are thrilled to announce the launch of our bare PCB board service to streamline your design workflow and help you bring your innovative ideas to life.

New Inventory Features Streamline Material Management

A display of some new features for the platform that enhances the the management of inventory and material at MacroFab.

About MacroFab

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.