Updates to MacroFab’s Bill Of Materials (BOM) Interface

We’ve added usability enhancements, and simplified the BOM screen for a more streamlined experience and greater performance. These updates will improve clarity, provide details that matter in an organized way, and make it faster to update your BOM.

Here’s a breakdown of features we’ve added to the BOM screen:

- Easy visualization of price breaks for components

- Add components from any distributor with live availability

- Faster workflow for filling out a new bill of materials with fewer clicks

- Ability to add to your bill of materials at any time

- Visual filters to quickly find issues

- New bulk operations (group, ungroup, DNP, delete)

The BOM screen is now designed to look more like a traditional list-based bill of materials, providing a more intuitive interface. We’ve included a price break graph with minimum order quantity (MOQ), and given you the ability to add any component, whether or not it’s available from a preferred distributor. A new BOM feature is the ability to select multiple components and group them, ungroup, do not place, or remove them. Additionally, we’ve given you the ability to buy parts from other distributors, for our Production Class Service. We will also show lead time for parts that are currently unavailable, making it easier for you to update your timeline.

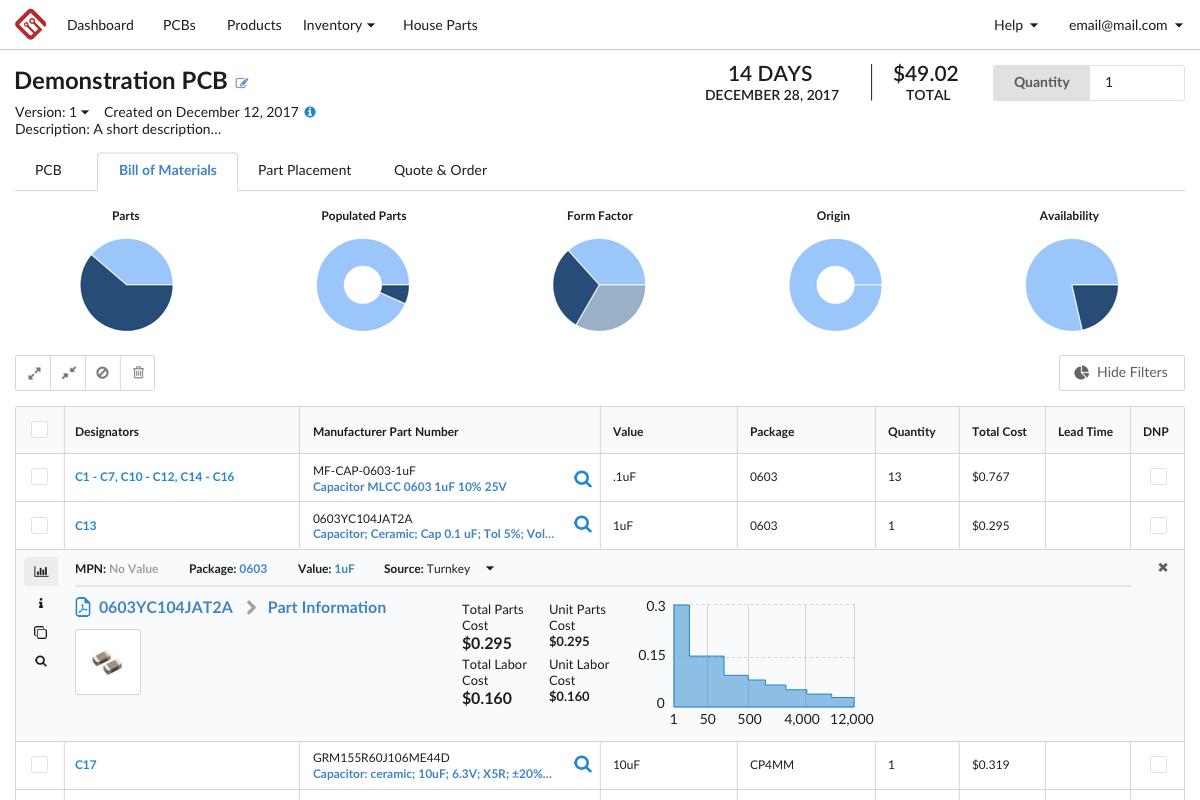

PCB Bill of Materials Example

By clicking within any of the interactive filter charts, you can quickly limit the displayed bill of materials items by key details.

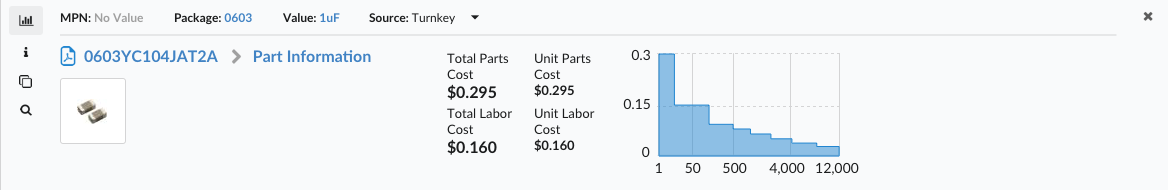

Price break graph and bulk operations

By clicking on any bill of materials row, you will now be able to see a graph that outlines price breaks for that part. This is extremely useful for larger production orders, so you and your team can see where savings will occur.

PCB Bill of Materials Price Break

Adding any component and matching to MPN

One of the main features in the BOM is you can now add any electronics component, from any screen within the platform, without having to upload a new BOM.You can add a part, even if it is unavailable, and we’ll display a lead time.

If you have an MPN, we will search for it and if there is an exact match, we will automatically select it. If there isn’t an exact match, our platform will do a search for the package and value, and you will be presented the top 3 matches, so that you can quickly choose the right part.

Redefining electronics manufacturing

MacroFab is redefining the electronics manufacturing experience from a manual, time-intensive, and error-prone process performed by large teams of people, into a real-time, streamlined, and connected software-driven experience. With our globally competitive prices available instantly, and an interface that provides more information in a clearer format, it’s now easier than ever for you to take control of your projects.

For any questions or comments regarding these updates, please email support@macrofab.com

Related Topics

Streamlined Mechanical BOM Management

Manage Mechanical Bills of Materials (MBOMs) with electrical BOMs in MacroFab's PCB platform. Streamline projects and save time with our new MBOM feature.

MacroFab's Bare PCB Option Helps You Develop Products Faster

We are thrilled to announce the launch of our bare PCB board service to streamline your design workflow and help you bring your innovative ideas to life.

New Inventory Features Streamline Material Management

A display of some new features for the platform that enhances the the management of inventory and material at MacroFab.

About MacroFab

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.