Renu Robotics

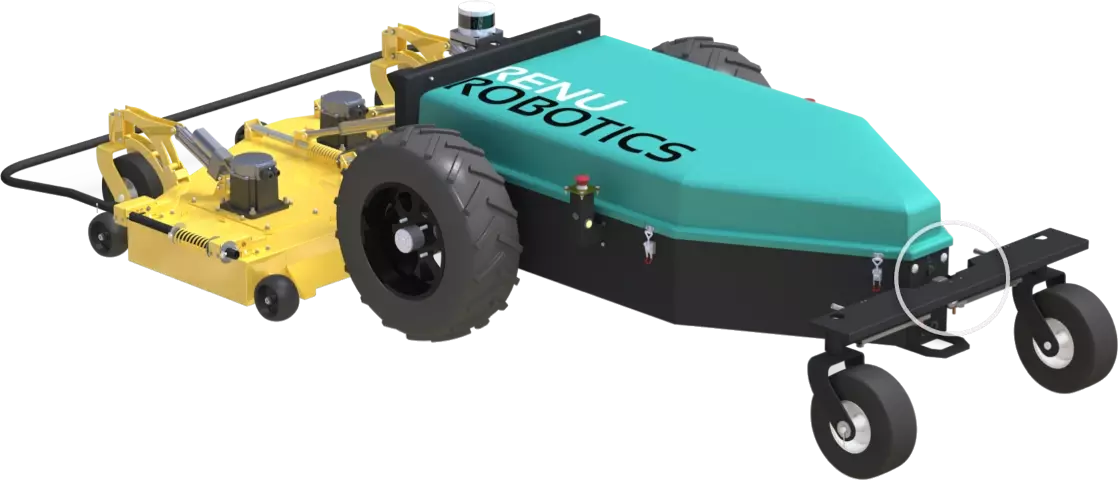

Renu Robotics is transforming the way solar and energy facilities manage onsite vegetation through their all-electric autonomous mowers capable of maintaining huge land plots.

Get to Know the Work:

Renu Robotics, based in San Antonio, sells all-electric autonomous mowers capable of maintaining huge land plots, saving operators from overseeing large manual crews or dealing with associated scheduling and possible accidents. Not only do Renu Robotics’ customers reduce vegetation management costs by 30-50% when they adopt the technology, but also save time and significantly lower carbon emissions.

Assessment

Initially, Renu Robotics was using MacroFab solely for prototyping. The company’s electrical engineers performed engineering and design validation tests through the platform, making revisions whenever necessary. In some cases, Renu Robotics would use MacroFab’s 10-day turnaround service to iterate and finalize products.

Challenge

Recognizing MacroFab could provide even more value to Renu Robotics, a MacroFab rep reached out to Renu officials to share more about the platform’s unique production model. Renu Robotics needed a flexible electronics manufacturing partner capable of evolving with the company over time.

Process

MacroFab serves as the front-end gateway to a vast network of thoroughly vetted, North American-based electronics manufacturing facilities. Electrical engineering teams have the freedom to choose where their components get produced based on up-to-date information about facility capacity, available parts, pricing, and other details. So, rather than commit volumes to a few manufacturers halfway across the world, MacroFab users can scale production up and down as needed, choosing facilities well-suited for specific production runs.

Our Solution

For these reasons, MacroFab’s model motivated Renu Robotics to move production to the platform. The company slowly ramped up production through the MacroFab platform (~80 units at a time). MacroFab facilities took care of PCB assembly for Renu Robotics’ mowers (aka “bots”), each requiring five different, complex PCBAs. They also apply a conformal coating to the PCBAs, ensuring they are rugged enough for outdoor operations.

After assembling the PCBAs, MacroFab manufacturers ship the components to Renu Robotics for final testing and final assembly.

Summary

Renu Robotics’ increased partnership with MacroFab has panned out well for the company. In 2022, Renu Robotics plans to produce more than 1,000 units through the platform. MacroFab will continue working on PCB assembly and send completed boards to Renu Robotics for final assembly.

Looking ahead, Renu Robotics is also planning to expand into other renewable energy industries, municipalities, and other various business sectors.