Companies Bring Electronics Production Home From Asia

Checkpoint

Reshoring represents a strategic decision that can lead to long-term growth and sustainability in an increasingly competitive global market.

Electronics are essential to various industries, such as automotive, communications, and medical equipment. However, the dominance of low-wage Asian manufacturing has led to complicated supply chains, risking trade disputes, tariffs, intellectual property theft, and natural disasters. In recent years, these risks have caused severe production disruptions, increased costs, and market share losses for many businesses.

Lately, numerous companies have begun reassessing their global value chains and moving electronics production closer to home. This trend is known as reshoring and nearshoring. Reshoring brings manufacturing back to the U.S., while nearshoring involves shifting operations to Canada or Mexico.

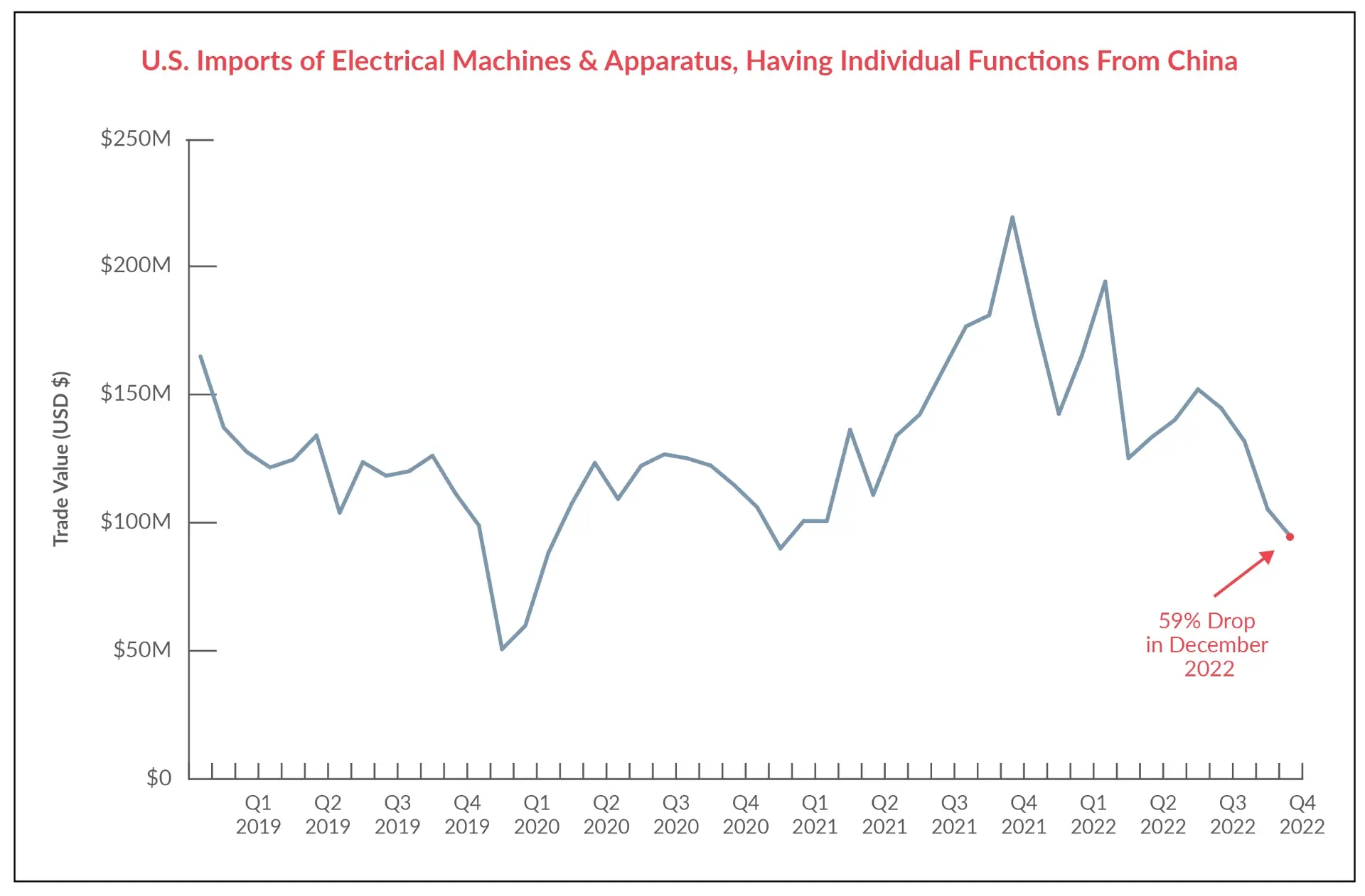

In December 2022, for instance, China’s electrical machines & apparatus exports fell by 59 percent compared to the previous year.

The Benefits of Reshoring and Nearshoring in Electronics Manufacturing

Companies are reshoring or nearshoring their electronics production due to several attractive benefits, including:

- Cost reduction: Regionalization can save companies money on transportation, inventory, labor, and taxes. Deloitte reports that reshoring can lower total landed costs by 5 - 20 percent compared to offshoring.

- Faster time-to-market: By shortening supply lines and removing intermediaries, companies canaccelerate product development cycles and respond more quickly to shifting customer demands.

- Enhanced quality and innovation: Companies can maintain higher quality standards and encourage product innovation by having greater control over their production processes and intellectual property rights.

- Increased resilience: By diversifying sourcing options and reducing dependence on remote suppliers, companies can mitigate disruption risks from geopolitical tensions, trade wars, pandemics, or natural disasters.

Real-World Examples of Reshoring and Nearshoring

Moving production back to North America offers companies more than just cost savings or logistical benefits; it represents a strategic decision that can lead to long-term growth and sustainability in an increasingly competitive global market.

Some companies that have recently reshored or nearshored their electronics production include:

Tesla: The electric vehicle manufacturer built a Gigafactory in Texas to produce car batteries and semiconductors and invested in battery R&D in California. These efforts aim to control the supply chain, reduce costs and risks, and improve quality and innovation. The company may also capitalize on government incentives from the CHIPS Act and Inflation Reduction Act (IRA). Consequently, Tesla is expected to enhance the competitiveness of electric mobility manufacturing in the U.S.

Ford: The automaker plans to invest $11.4 billion in constructing electric vehicle plants in Kentucky and Tennessee, utilizing batteries made by S.K. Innovation in Georgia. The company relocated its electric vehicle production to the U.S. to meet growing demand for eco-friendly cars, reduce dependence on foreign suppliers, leverage domestic talent and resources, and benefit from IRA government incentives.

G.E. Healthcare: The medical device manufacturer shifted some ventilator production from China to Wisconsin during the COVID-19 pandemic and partnered with Ford to produce ventilators at a Michigan plant. G.E. moved some ventilator production to support national health security, reduce lead times and delivery costs, and improve quality and reliability. G.E. Healthcare is a leading medical device producer.

Apple: The tech giant pledged to invest $430 billion in the U.S. over the next five years, including expanding semiconductor design operations in California and Texas, supporting American suppliers, and contributing to a new chip consortium led by Intel. Apple’s decision aims to enhance innovation, protect intellectual property, diversify supply chain sources, and get government incentives from the CHIP Act. With this move, Apple is expected to increase product differentiation, quality, and performance.

Motorola Solutions: In 2021, the company established a new manufacturing facility for video security in Richardson, Texas, focusing on fixed video security cameras for government and enterprise clients. Additionally, some radio production operations were moved from China to Illinois. Motorola Solutions cited benefits from reshoring, including reduced lead times, enhanced quality, and lower costs. These advantages stemmed from better customer communication and collaboration, decreased lead times and inventory expenses, and improved quality control and customization options.

In conclusion, reshoring and nearshoring offer significant advantages for American companies, as illustrated by the above real-world examples. By bringing production closer to home, companies can enjoy reduced lead times, improved quality, and lower costs, among other benefits. Advantages arise from enhanced communication and collaboration with customers, streamlined inventory management, and superior quality control and customization options.

If your company is seeking to optimize its supply chain and manufacturing processes, it’s worth considering the benefits of reshoring or nearshoring. Taking tips from successful companies, like the ones mentioned above, can help you improve efficiency, reduce costs, strengthen customer relationships, and boost your company’s competitiveness.

Related Topics

What’s Changing in US Electronics Manufacturing

In the coming years, reshoring electronics manufacturing may be the key to maintaining the US economy's stability.

Surviving the Warehousing Squeeze

The warehousing crunch has put a strain on electronics companies that rely on quick delivery of electronic components or PCBAs, especially from overseas.

Electronics Made in America? You Need Workers First

Reshoring offers a solution to persistent problems of instability, lending companies the resilience needed to succeed now and into the future.

Learn More About Reshoring with MacroFab

Reshoring ElectronicsAbout MacroFab

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.