Top 5 Benefits of AI-Powered Electronic Manufacturing Services (EMS)

The Future of EMS is Intelligent

Electronics OEMs today face relentless pressure to deliver faster, control costs, and manage unpredictable supply chains. Traditional EMS partners often lack the agility and insight to keep pace with this complexity.

MacroFab changes that.

By combining the scale of a North American manufacturing network with the intelligence of FabIQ™ AI engine, MacroFab enables OEMs to quote, source, build, and scale electronics smarter and faster than ever before.

Here’s how MacroFab turns AI and digital infrastructure into a competitive edge across your product lifecycle.

1. Smarter, Real-Time BOM Optimization

Sourcing and managing BOMs manually can be slow, error-prone, and reactive. FabIQ™ instantly analyzes your uploaded BOM and provides:

- Part-level cost insights

- Lead time visibility

- Tariff impact

- Regionally available alternatives

The system automatically suggests optimal substitutes helping you avoid delays, reduce costs, and navigate sourcing risks before they derail your schedule.

MacroFab Advantage: Real-time BOM suggestions, proactive supply chain risk detection, and sourcing recommendations all built into the platform.

2. Intelligent Factory Allocation for Every Build

Every product has unique manufacturing needs. MacroFab’s digital platform ensures your build is routed to the best-fit factory across its network in North America based on:

- Volume and complexity

- Regional production goals

- Real-time factory capacity and specialization

This allocation ensures faster turnaround, optimized logistics, and high-quality results whether you're scaling to 10,000 units or prototyping 10.

MacroFab Advantage: Smart, streamlined factory matching that aligns with your product’s needs—without the headaches of manual vendor management.

3. Built-In Tariff and Cost Protection

Tariff policy shifts can create sudden cost increases that derail budgets. MacroFab’s platform actively supports tariff-smart sourcing and includes exclusive programs like Tariff Protection℠, which locks in pricing for all prepaid PCB assembly orders.

This means no retroactive charges, even if tariff rates rise after your order is placed.

MacroFab Advantage: Transparent, stable pricing and automatic protection from unexpected tariff changes so your cost estimates stay solid.

4. AI That Learns With You

FabIQ™ doesn’t just analyze your BOM once, it gets better with every order. Trained on over 50,000 PCB designs and more than 10 years of supply chain and pricing data, FabIQ™ continuously improves its recommendations and cost optimization strategies.

MacroFab Advantage: A smarter supply chain with every build—powered by real-world manufacturing and sourcing intelligence.

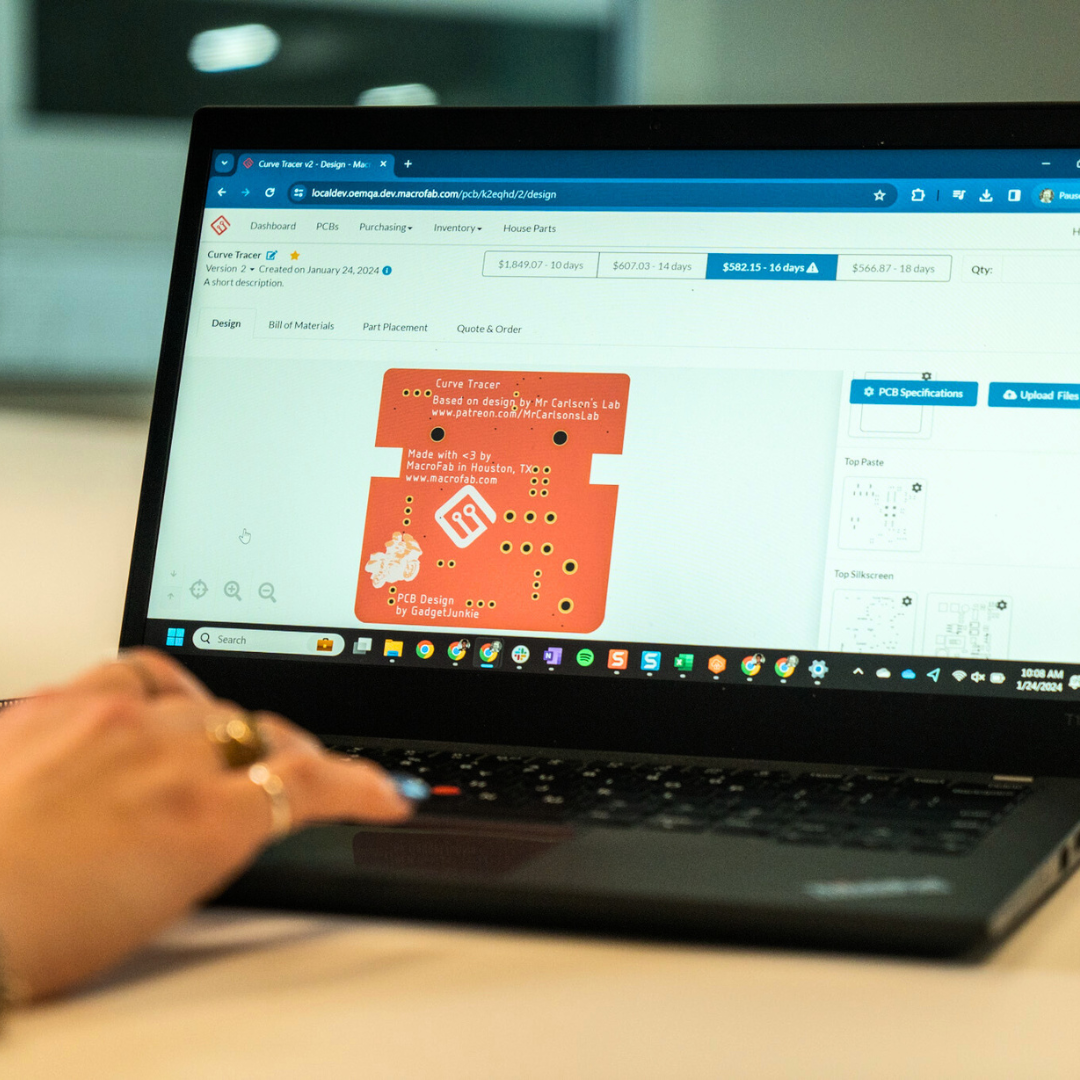

5. One Platform, Total Control

MacroFab consolidates the entire electronics manufacturing process into a single digital platform from BOM upload to order delivery:

- Instant pricing and quotes

- BOM and revision management

- Factory assignment and status tracking

- Centralized visibility across all builds

You gain more control, better data, and less time spent chasing vendors or syncing spreadsheets.

MacroFab Advantage: End-to-end visibility, faster decision-making, and total operational clarity across your product catalog.

Why MacroFab is the Future of EMS

AI-powered EMS isn’t a future trend. It’s the current standard for OEMs who want to build smarter. With MacroFab, it’s not just possible. It’s proven.

From BOM optimization to production fulfillment, MacroFab’s digital manufacturing platform gives your team the tools to reduce costs, avoid surprises, and scale with confidence no matter the complexity or volume.

Whether you're building 10 units or scaling to 10,000, MacroFab is how modern electronics gets made.

Related Topics

Lock In Your Build Price with Tariff Protection

No surprises at checkout. Learn how MacroFab’s Tariff Protection keeps your build costs stable—even when global tariffs spike

11 Reasons Engineers Are Moving to US PCB Manufacturers Like MacroFab

Discover why engineers are shifting from offshore to US PCB manufacturers. Learn how MacroFab delivers faster, tariff-reduced, high-quality PCB assembly

Reduce Production Costs with Direct Ship℠

See how MacroFab's Direct Ship℠ reduces the impact of tariffs and lowers your production costs for electronics.

Get a Protected Quote Today

Start Your Build with Tariff ProtectionFAQs: AI in Electronics Manufacturing

Curious how AI is transforming the way electronics get built? Whether you're managing a single prototype or scaling to full production, our AI-powered EMS platform—FabIQ™—helps you move faster, cut costs, and stay ahead of sourcing risks. We've answered some of the most common questions engineers ask about AI in manufacturing so you can make smarter decisions, faster.

AI-powered EMS combines traditional electronics manufacturing with AI tools to optimize quoting, sourcing, and production; saving time and cost. MacroFab’s FabIQ™ engine is a leading example.

MacroFab’s FabIQ™ instantly analyzes your BOM, flags risk components, suggests regionally available alternatives, and reveals real-time lead times...eliminating delays before they even start.

Yes. Platforms like MacroFab's FabIQ™ uses AI to identify cheaper component alternatives, reduce sourcing delays, and lock in tariff-protected pricing.

Absolutely. MacroFab’s platform automatically routes your build to the best-fit North American factory based on complexity, volume, and availability—faster and more accurately than manual processes.

Not at all. MacroFab supports everything from one-off prototypes to full-scale production. AI just makes the process smarter at every stage.

About MacroFab

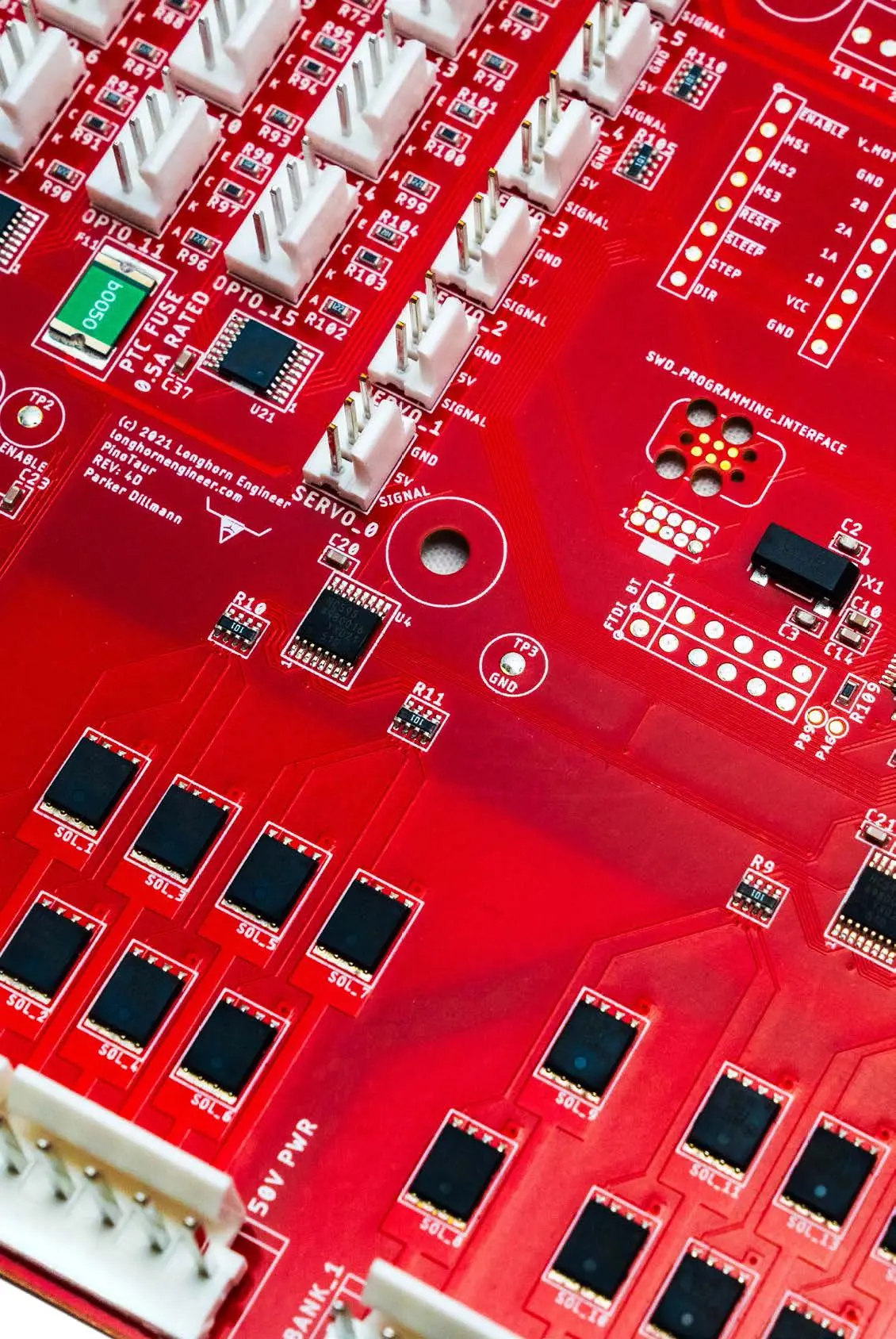

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.