Digital Electronics vs Traditional EMS:

Fab IQ - Digital EMS

In a market where every week counts and margins are tight, the way you build electronics can be a competitive edge or a bottleneck. For engineers evaluating manufacturing strategies, understanding the trade-offs between digital manufacturing platforms and traditional electronic manufacturing services (EMS) is critical.

Let’s explore how each approach stacks up in terms of cost, speed, and flexibility, and how MacroFab’s AI-powered EMS platform is reshaping expectations.

1. Cost Efficiency

Traditional EMS

Traditional EMS providers often rely on static quoting processes, regional sourcing limitations, and manual coordination. This leads to:

- Higher NRE (non-recurring engineering) fees

- Quoting delays and unpredictable pricing

- Difficulty sourcing low-cost components at scale

Digital EMS (MacroFab)

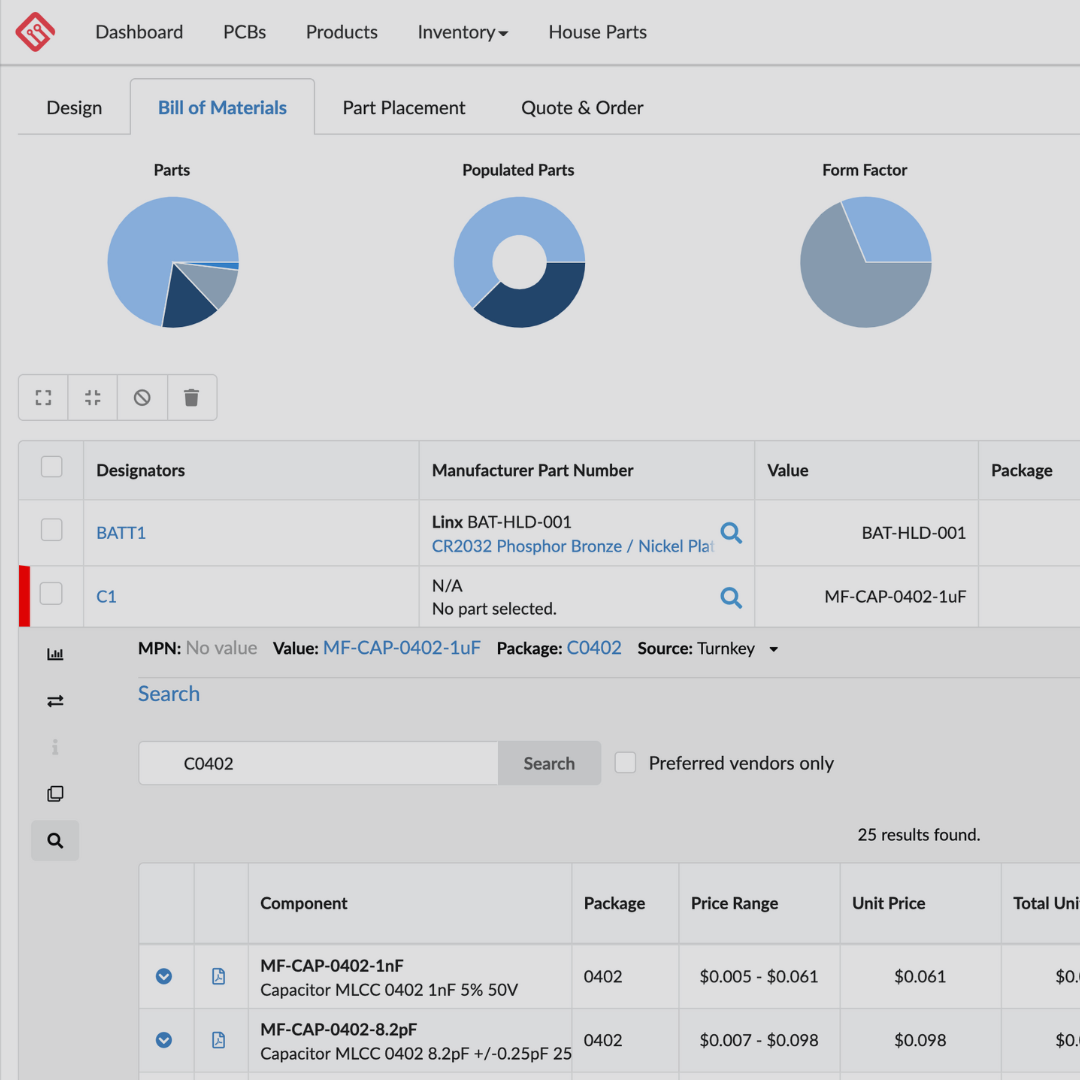

MacroFab’s digital platform uses AI-driven quoting and a network of North American factories to deliver:

- Instant, transparent pricing even for complex PCB assemblies

- Dynamic cost savings through alternative part discovery

- Automated sourcing that taps into real-time global supply chain data

Result: Lower TCO (Total Cost of Ownership) with less manual oversight and fewer sourcing surprises.

2. Speed to Market

Traditional EMS

Turnaround times in traditional setups can stretch due to:

- Manual quoting and PO processing

- Delayed responses to engineering changes

- Rigid production schedules

Digital EMS (MacroFab)

Speed is a built-in feature of MacroFab’s model:

- Prototypes and low-volume orders can be placed with a credit card; no paperwork required

- AI-powered workflows automate BOM analysis, quoting, and scheduling

- Real-time visibility into production and delivery timelines

Result: Cut your time to market by weeks without sacrificing quality or control.

3. Flexibility and Scalability

Traditional EMS

Scaling with traditional EMS often requires requalification, new contracts, and managing multiple suppliers for different volumes and product lines.

Digital EMS (MacroFab)

MacroFab gives engineers a single interface to manage their entire product catalog, with scalability baked in:

- Automatically matches product specs to factory capabilities

- Supports prototyping, high-mix low-volume, and full production

- Multi-buyer and team collaboration features simplify internal coordination

Result: Adapt rapidly to design changes, demand fluctuations, and supply chain challenges without switching vendors.

Why This Matters for Decision-Makers

As the industry shifts toward software-enabled hardware, your manufacturing partner needs to be as agile as your engineering team. MacroFab’s FabIQ isn’t just faster and cheaper; it’s designed for the realities of modern product development: distributed teams, tight timelines, and complex BOMs.

For electrical engineers and operations leaders looking to optimize their electronics manufacturing, the choice is clear. Traditional EMS may still work for legacy systems, but digital manufacturing platforms like MacroFab are built for the future.

Related Topics

Factories Fill Idle Capacity with EMS Marketplaces

How smart PCB assembly factories use digital EMS marketplaces like MacroFab to fill idle capacity, boost utilization, and grow revenue effortlessly.

How Electronics Manufacturing Services (EMS) Powers Efficient Production

This blog glances at how EMS is an effective services to produce a good design and sellable products. Being a great tool to turn ideas into reality.

Why You Need Elastic Manufacturing Capacity for PCBA Mfg

Joanne Moretti and Philip Stoten explore elastic capacity in manufacturing and how AI-driven smart software can further enhance this elasticity.

Get a Protected Quote Today

Start Your Build with Tariff ProtectionFAQs: Digital vs Traditional EMS

This FAQ breaks down how solutions like MacroFab’s AI-powered platform compare to legacy EMS in cost, speed, flexibility, and scalability so you can make smarter, faster decisions for your next PCB build.

Traditional EMS relies on manual quotes and slow processes. Digital platforms like MacroFab automate sourcing, quoting, and production for faster, more flexible builds.

Yes. MacroFab reduces costs through AI-driven part sourcing, transparent pricing, and fewer hidden fees compared to legacy EMS providers.

Definitely. MacroFab scales from single-board prototypes to high-volume runs—no supplier switching needed.

With instant quoting, online ordering, and real-time tracking, MacroFab cuts weeks off the typical EMS lead time.

Yes. MacroFab supports advanced and regulated builds through a vetted North American factory network with full visibility and traceability.

About MacroFab

MacroFab offers comprehensive manufacturing solutions, from your smallest prototyping orders to your largest production needs. Our factory network locations are strategically located across North America, ensuring that we have the flexibility to provide capacity when and where you need it most.

Experience the future of EMS manufacturing with our state-of-the-art technology platform and cutting-edge digital supply chain solutions. At MacroFab, we ensure that your electronics are produced faster, more efficiently, and with fewer logistic problems than ever before.

Take advantage of AI-enabled sourcing opportunities and employ expert teams who are connected through a user-friendly technology platform. Discover how streamlined electronics manufacturing can benefit your business by contacting us today.